Table of contents

Page

1

.

OPERATING RANGE …………………………………………………………………………….….1

2

.

SPECIFICATION………………………………………………………………………………….… 2

2-1 Unit specifications ………………………………………………………………

2-2 Major component specifications ………………………………………………

2-3 Other component specifications ………………………………………………

3

.

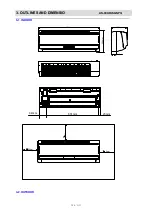

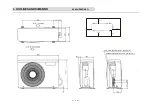

OUTLINES AND DIMENSIONS…………………………………………………………..…..…… 6

3-1 INDOOR ………………………………………………………………………

3-2 OUTDOOR ……………………………………………………………………..

4

.

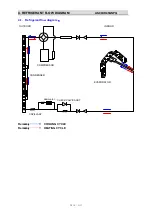

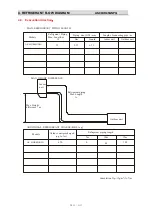

REFRIGERANT FLOW DIAGRAM ………………………………………………………..………8

4-1 Refrigerant flow diagram ……………………………………………………………………..

4-2 Evacuation procedures ……………………………………………………………………..

4-3 Evacuation direction ……………………………………………………………………..

5

.

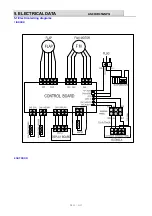

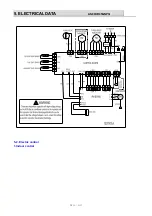

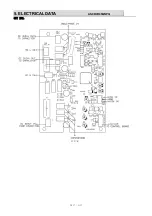

ELECTRICAL DATA ………………………………………………………………………………..11

5-1 Electric wiring diagrams ……………………………………………………………………..

5-2 Electric control ……………………………………………………………………..

5-3 Sensor parameter ……………………………………………………………………..

6

.

CONTROL MODE 16 6-1 control mode …………………………………………………….....18

7

.

TROUBLESHOOTING………………………………………………………………………….… 26

7-1 Error codes ………………………………………………………………………….

7-2 Service flow chart ……………………………………………………………………

8

.

CHECKING COMPONENTS……………………………………………………………………. 32

8-1 Check refrigerant system ……………………………………………………………………

8-2 Check parts unit ……………………………………………………………………

9

.

DISASSEMBLY INSTRUCTIONS ………………………………………………………………..38

9-1 Indoor ……………………………………………………………………

9-2 Outdoor ……………………………………………………………………

10

.

PARTS LIST ………………………………………………………………………………….…45

10-1 Indoor ……………………………………………………………………

10-2 Outdoor ……………………………………………………………………

第 2/51页