7

English

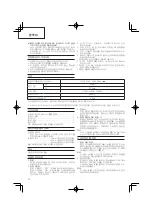

CUTTING PROCEDURES

1. Place the saw body (base) on the lumber, and align

the intended line of cut with the saw blade, using the

notch at the front of the base. This relationship of base

to lumber should remain unchanged regardless of the

inclination of the base (

Fig. 5

).

2. Turn ON the switch before the saw blade contacts the

lumber. The switch is turned ON when the trigger is

squeezed, and turned OFF when the trigger is released.

3. Moving the saw straight at a constant speed will

produce optimum cutting.

CAUTION

Prior to cutting operation, make sure the material you

are going to cut. If the material to be cut is expected to

generate harmful / toxic dusts, make sure the dust bag or

appropriate dust extraction system is connected with dust

outlet tightly.

Wear the dust mask additionally, if available.

○ Before starting to saw, confirm that the saw blade has

attained full-speed revolution.

○ Should the saw blade be stopped or made an abnormal

noise while operating, promptly turn OFF the switch.

○ Always take care in preventing the power cord from

coming near to the revolving saw blade.

○ Using the Circular Saw with the saw blade facing

upwards or sideways is very hazardous. Such

uncommon applications should be avoided.

○ When cutting material, always wear eye protection.

○ When finished a job, disconnect the plug from the

receptacle.

MOUNTING AND DISMOUNTING THE SAW

BLADE

CAUTION

To avoid serious accident, ensure that the switch is in the

OFF position, and the power source is disconnected.

1. Dismounting the saw blade

(1) Set the cutting volume at maximum, and place the

Circular Saw as shown in

Fig. 6

.

(2) Depress the lock lever, lock the spindle, and remove the

hexagonal-flange bolt with the box wrench.

(3) While holding the lower guard lever to keep the lower

guard fully retracted into the saw cover, remove the saw

blade.

2. Mounting the saw blade

(1) Thoroughly remove any sawdust which has accumulated

on the spindle, bolt and washers.

(2) As shown in

Fig. 7

, the side of Washer (A) with a

projected center the same diameter as the inner

diameter of the saw blade and the concave side of

Washer (B) must be fitted to the saw blade sides.

* Washer (A) is supplied for 3 types of saw blades

with the hole diameters of 16 mm, 20 mm and

30 mm. (When buying the Circular Saw, one type of

washer (A) is supplied.)

In case the hole diameter of your saw blade does

not correspond to that of washer (A), please contact

the shop where you purchased the Circular Saw.

(3) To assure proper rotation direction of the saw blade, the

arrow direction on the saw blade must coincide with the

arrow direction on the saw cover.

(4) Using the fingers, tighten the hexagonal-flange bolt

retaining the saw blade as much as possible. Then

depress the lock lever, lock the spindle, and thoroughly

tighten the bolt.

CAUTION

After having attached the saw blade, reconfirm that the lock

lever is firmly secured in the prescribed position.

MAINTENANCE AND INSPECTION

1. Inspecting the saw blade

Since use of a dull saw blade will degrade efficiency and

cause possible motor malfunction, sharpen or replace

the saw blade as soon as abrasion is noted.

2. Inspecting the mounting screws

Regularly inspect all mounting screws and ensure that

they are properly tightened. Should any of the screws

be loose, retighten them immediately. Failure to do so

could result in serious hazard.

3. Inspecting the carbon brushes (Fig. 8)

The motor employs carbon brushes which are

consumable parts. Since an excessively worn carbon

brush can result in motor trouble, replace the carbon

brushes with new ones having the same carbon brush

No. shown in the figure when it becomes worn to or

near the “wear limit”. In addition, always keep carbon

brushes clean and ensure that they slide freely within

the brush holders.

4. Replacing carbon brushes (Fig. 9)

Disassemble the brush caps with a slotted-head

screwdriver. The carbon brushes can then be easily

removed.

5. Maintenance of the motor

The motor unit winding is the very “heart” of the power

tool. Exercise due care to ensure the winding does not

become damaged and/or wet with oil or water.

6. Adjusting the base and saw blade to maintain

perpendicularity:

The angle between the base and the saw blade has been

adjusted to 90°, however should this perpendicularity be

lost for some reason, adjust in the following manner:

(1) Turn the base face up (

Fig. 10

) and loosen the wing-bolt

(A).

(2) Apply a square to the base and the saw blade and

turning the screw with a screwdriver, shift the position

of the base to produce the desired right angle (

Fig. 11

).

CAUTION

In the operation and maintenance of power tools, the

safety regulations and standards prescribed in each

country must be observed.

NOTE

Due to HiKOKI’s continuing program of research and

development, the specifications herein are subject to

change without prior notice.

Summary of Contents for C 7ST

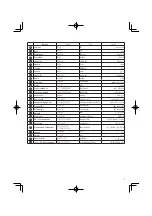

Page 2: ...1 2 3 4 5 6 7 8 9 10 11 12 2 43 6 mm 17 mm 0 45 ...

Page 22: ...22 ...

Page 23: ...23 ...