—

1

—

1.

PRECAUTIONS BEFORE STARTING OPERATION

1)

Safety precautions

:

(

1

)

When turning the power on, keep your hands and fingers away from the area around/under the needle

and the area around the pulley.

(

2

)

Power must be turned off when the machine is not in use, or when the operator leaves the seat.

(

3

)

Power must be turned off when tilting the machine head, installing or removing the “V” belt,

adjusting the machine, or when replacing.

(

4

)

Avoid placing fingers, hairs, bars etc., near the pulley, “V” belt, bobbin winder pulley, or motor when

the machine is in operation.

(

5

)

Do not insert fingers into the thread take-up cover, under/around the needle, or pulley when the

machine is in operation.

(

6

)

If a belt cover, finger guard, eye guard are installed, do not operate the machine without these safety

devices.

2)

Precautions before starting operation

:

(

1

)

If the machine’s oil pan has an oil sump, never operate the machine before filling it.

(

2

)

If the machine is lubricated by a drop oiler, never operate the machine before lubricating.

(

3

)

When a new sewing machine is first turned on, verify the rotational direction of the pulley with the

power on. (The pulley should rotate counterclockwise when viewed from the pulley)

(

4

)

Verify the voltage and (single or three) phase with those given on the machine nameplate.

3)

Precautions for operating conditions

:

(

1

)

Avoid using the machine at abnormally high temperatures

(

35

or highe

℃

r

)

or low temperatures

(

5

℃

or lower

)

.

(

2

)

Avoid using the machine in dusty conditions.

2.

SPECIFICATIONS

Model GC24698-BRHL/BLHL

Max.sewing speed

800r.p.m

Stitch length

10mm

Presser-foot stroke

8mm By hand 16mm By pneumatic

Needle size

DP×17 17# -23#

Lubrication system

Manual lubrication

Highness of post-bed

670mm

Motor 550W

Sevor

motor

3.

LUBRICATION(Fig.1,Fig.2,Fig.3,Fig.4)

When a new sewing machine is used for the first time, or sewing machine left out of use for considerably long

time is used again, replenish a suitable amount of oil to the portions indicated by arrow in the below figure.

Filling the oil to the fount timely.

Summary of Contents for GC24698-BLHL

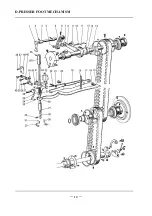

Page 9: ...A ARM BED MECHANISM 7 7 ...

Page 11: ...B THREAD TENSION REGULATOR MECHANISM 9 9 ...

Page 13: ...C ARM SHAFT MIDDLE SHAFT MECHANISM 11 11 ...

Page 16: ...D PRESSER FOOT MECHANISM 14 14 ...

Page 19: ...E NEEDLE BAR THREAD TAKE UP MECHANISM 17 17 ...

Page 22: ...F STITCH REGULATOR MECHANISM 20 20 ...

Page 24: ...G LOWER SHAFT FEEDING SHAFT MECHANISM 22 22 ...

Page 27: ...H HOOK SADDLE MECHANISM 25 25 ...

Page 29: ...I OIL LUBRICATION MECHANISM 27 27 ...

Page 31: ...J ACCESSORIES 29 29 ...