14

Trouble shooting

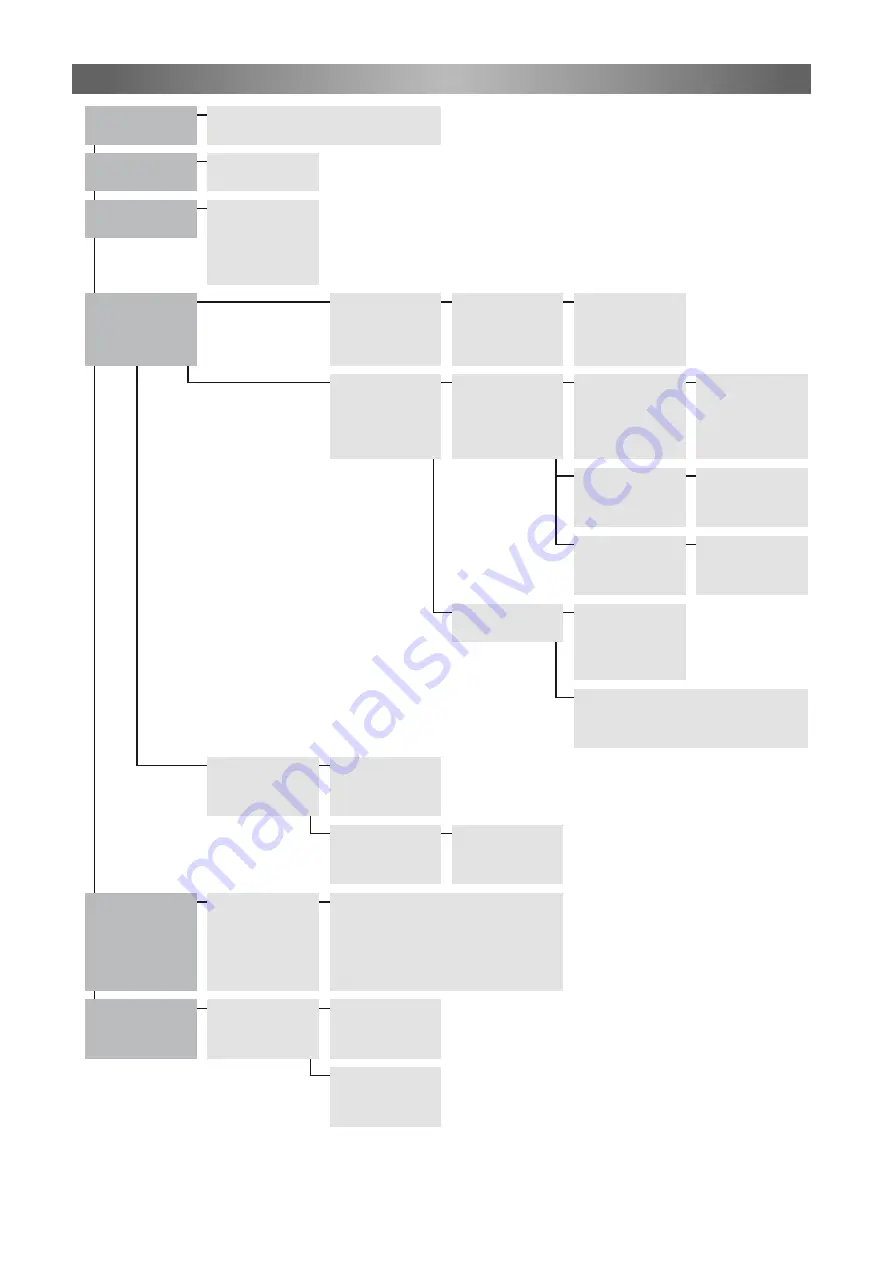

by qualified personnel

The machine

does not work.

The canister(s) is / are

empty.

The fluid is viscous.

The water does not

reach the brush(es)

when the machine is

switched on.

The detergent /

disinfec tant of the

hand washing station

is not output at all

or with insufficient

quantity only when

using the station.

The turnstile does not

enable access.

The power supply is interrupted or one of the components

failed. Please consult qualified specialists.

Change the canister.

Try to drawn in clear

water. When the ma-

chine operates correctly,

dilute the fluid upstream

of the canister and/or

change the nozzle.

Is there a valve installed

upstream to the

machine?

Check in the system

setting how big the

output quantity is and

change it.

Check if the hygiene

station enables hand

cleaning.

Check whether the valve

for setting the water

quantity is not fully

open.

(*) Remove the

hose from the check

valve of the dosing

system. Place your finger

to feel if there is any

negative pressure.

In the affirmative, open

the valve installed up-

stream to the machine.

Inspect if there is any foreign matter in the feeding line

blocking the flow. Test the faultless function of the two

spray nozzles and sensors.

In the affirmative, get

the turnstile tested for

mechanical function by

qualified personnel.

In the negative, the

solenoid valve does not

open.

In the negative, disinfect

the hands properly

according to instruction.

In order to check

this, close the valve

completely and check

whether the fluid is

drawn in.

Sucking effect present.

Sucking effect absent.

Get the solenoid valve

replaced by a qualified

specialist, if required.

If the cleaning fluid is

not drawn in, proceed

to (*).

Make sure that the

suction hose or suction

filter is not clogged by

depositions.

Make sure that the

suction hose is free of

damage.

Check whether the

existing nozzle is not

clogged.

Dismount the check valve. Check the

two O-ring seals of the cone and spring (if required,

replace the complete dosing flap).

Remove any clogging

or replace the parts.

Do not forget to fit the

filter on to the inlet of

the hose.

In the affirmative,

change the hose. Do not

forget to fit the filter on

to the inlet of the hose.

If the nozzle is clogged,

eliminate such clogging

or replace the nozzle.

Dismantle the nozzle and

clean the nozzle of the

dosing system because

depositions may have

built up.