4 • Service Manual — COATS Model IBS 2000

Direct Drive

Servicing

Service should be performed only by a factory trained

COATS

®

Service Technician. The troubleshooting and

service procedures in this manual are arranged to allow

rapid and thorough service. The steps are:

• Preliminary Inspection

• Functional Checks

• Repair Of Failure

• Replacement Or Adjustment

• Functional Checks

Identification of replacement parts required can be

accomplished by using the pictorial breakdown and index

in this manual. It is important that the FUNCTIONAL

CHECKS be performed IN SEQUENCE and the PROB-

LEM ISOLATED. If an adjustment is made, the entire

FUNCTIONAL CHECK must be performed SUCCESS-

FULLY before the balancer can be considered available

for service.

Equipment Needed

1.

AC / DC - Volt / Ohm meter (DVM).

2.

Test Wheel - Domestic 14" x 6" steel wheel with a

center hole suitable for mounting with a back cone. A

new 195/70/14 tire properly mounted and inflated, bal-

anced to within 0.02 ounces should be part of this wheel

assembly. The lateral run out of this wheel should be less

than 1/8". Modeling clay and 4 oz. test weight.

3.

Flat and Phillips screw drivers, and dead blow hammer.

4.

Tester for phone cables and jacks. (Modapt adaptor,

Contact East Part #118-785, call 1-800-225-5334 to order.)

5.

Thread locking anaerobic (Loctite 242 or equivalent).

Retaining compound (Loctite 601 or equivalent).

6.

Torque Wrench & a 5/16 X 6" hex socket for the

torque wrench.

7.

Small Allen wrenches, pot adjusting tools, & a 3/8"

nut driver.

8.

Chip extractor tool, Ammco part # 29977.

9.

A dial indicator (runout gauge) , Ammco part # 2850,

or 29752.

10.

Sockets: 3/8, 7/16, 3/4, 1/2, 9/16 inch, a speed han-

dle, or ratchet.

11

. A drill and 1/8" drill bits, pop rivet gun, and 1/8" rivets.

12.

A 7/16" - 3/8" box end wrench, and cutters for banding.

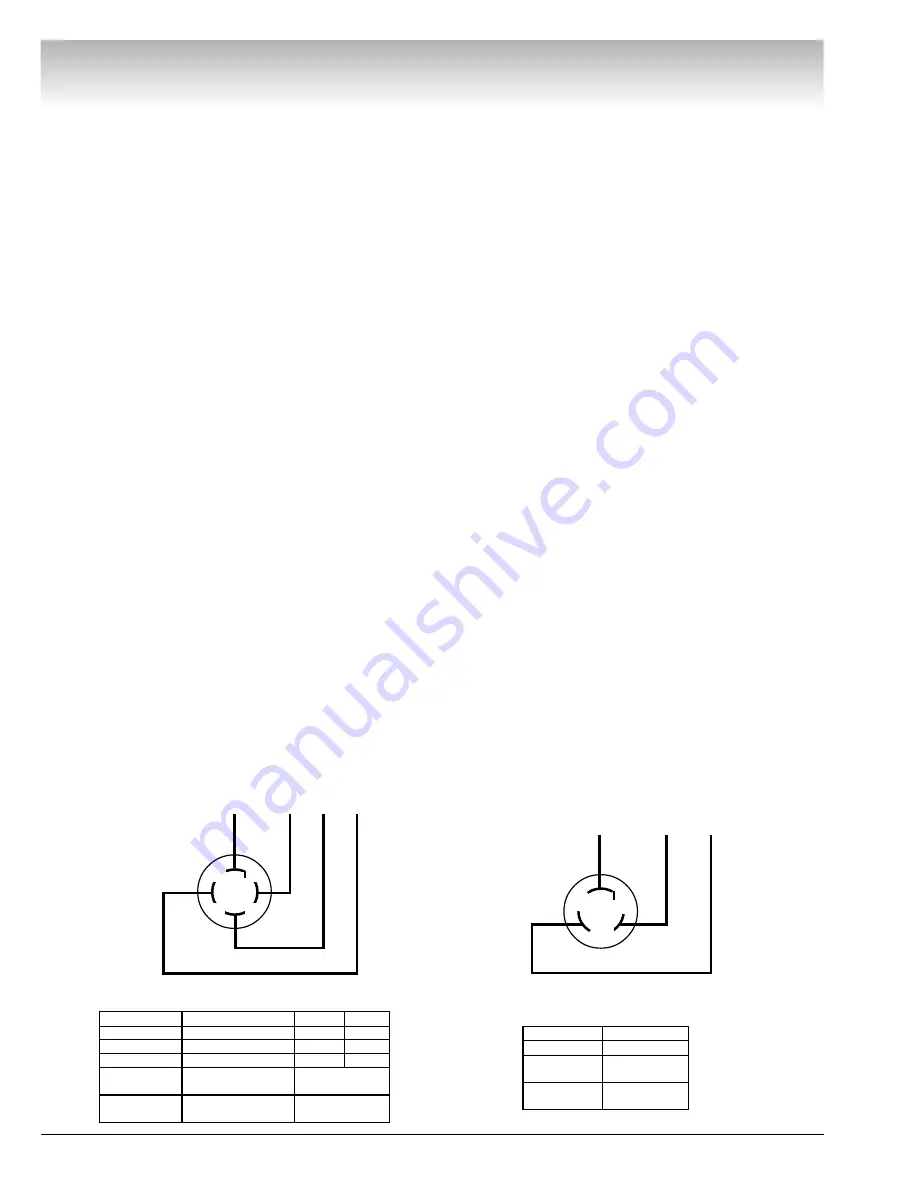

Voltage & Phase Checking Procedure

1.

Unplug the Balancer from the power source.

2.

Perform all voltage checks shown in the appropriate

diagram and chart at the power receptacle. If one or all

voltage measurements is faulty be sure to check the sta-

tus of the circuit breakers that supply the Balancer.

3.

Check from one of the power terminals to the

ground terminal to verify a ground is present. The voltage

measurement should be approximately one half of the

available voltage (i.e. 220V should read 110V).

Note: If any faults are found in the above pro-

cedure, it is the responsibility of the owner.

COATS

®

authorized service personnel are not

responsible for wiring within the building.

4.

Plug the balancer into a power source.

5.

Use an Ohmmeter to check the resistance between

the frame of the balancer and the building ground. The

resistance should be less than 1 ohm. If the resistance

measurement is greater that one (1) ohm, check the

power cord plug and frame connection for proper contact.

RED

WHITE

GREEN

GROUND

X

Y

Z

BLACK

GREEN

BLACK

RED

GROUND

A

B

THREE PHASE VOLTAGE REQUIREMENTS / INFORMATION

208V/220V/230V

380V

460V

X - Y

195-250

370-420

420-480

X - Z

195-250

370-420

420-480

Y - Z

195-250

370-420

420-480

Plug

Installed

Hubbell 2421

Hubbell 2431

Required

Hubbell 2420 or

Hubbell 2430 or

Mating Outlet

Equivalent

Equivalent

SINGLE PHASE VOLTAGE

REQUIREMENTS/ INFORMATION

208V/220V/230V

A - B

195 - 250

Plug

Hubbell

Installed

5466-C

Required

Hubbell 5462 or

Mating Outlet

Equivalent

Summary of Contents for Coats IBS 2000

Page 2: ...ii Service Manual COATS Model IBS 2000 Direct Drive...

Page 26: ...22 Service Manual COATS Model IBS 2000 Direct Drive Motor Controller Diagram...

Page 36: ...32 Service Manual COATS Model IBS 2000 Direct Drive IBS 2000 Wiring Diagrams...

Page 37: ...Service Manual COATS Model IBS 2000 33 Direct Drive...

Page 38: ...34 Service Manual COATS Model IBS 2000 Direct Drive...

Page 39: ...Service Manual COATS Model IBS 2000 35 Direct Drive...