XPM 80™

Thermal Printer Family

HENGSTLER

Part No. D 690 019

Mod. No. 4 051015 Eli1

page 28 of 32

9. Troubleshooting

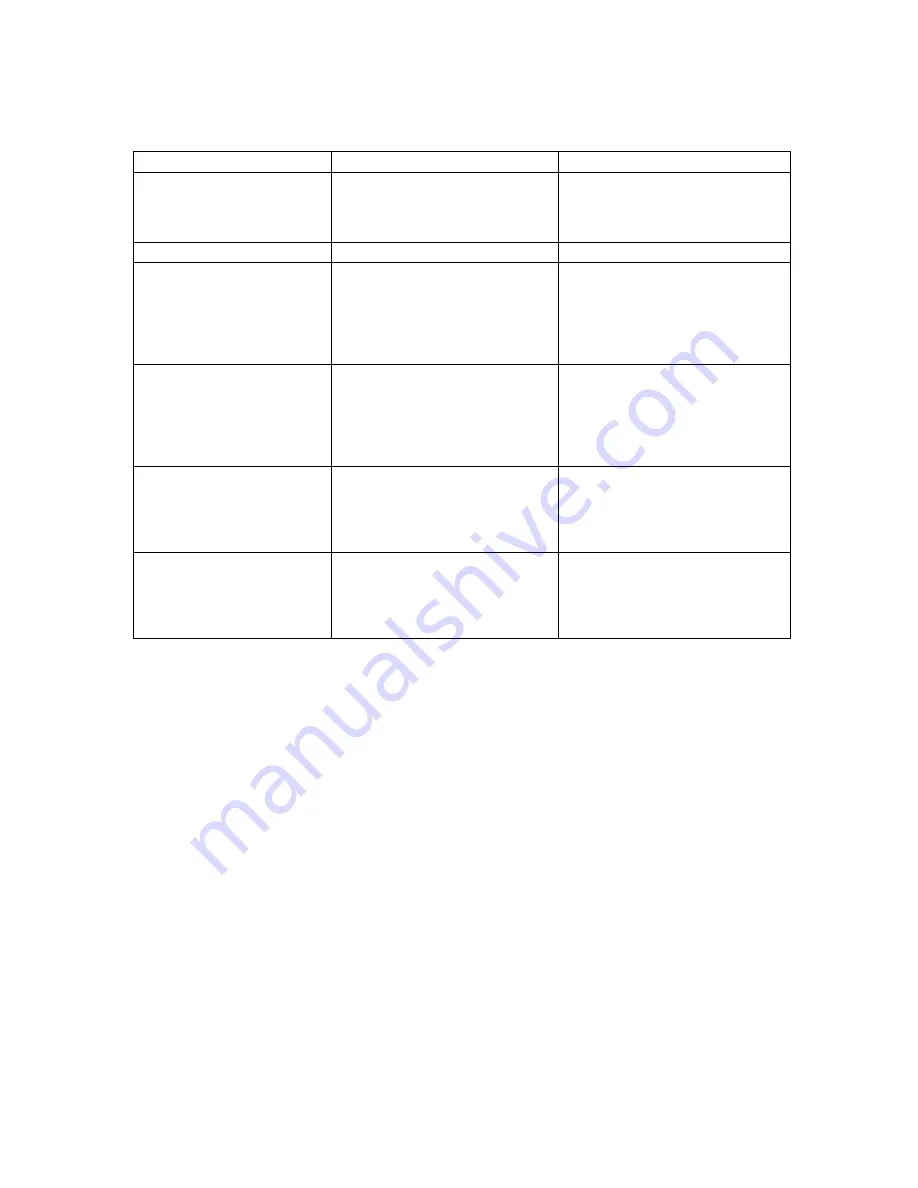

Symptom

Possible Cause

Corrective Action

No LEDs light on printer

1. Power not connected

2. PCB mounted fuse blown

1. Check line cord and outlet

2. Return printer for fuse

replacement; not field

replaceable

LEDs flashing

See Section “LED Indicators”

See Section “LED Indicators”

Dual-Feed unit will not run

when paper inserted

1. If paper has been ejected by

DFU control button, it must be

completely removed from

DFU and reinserted to feed.

2. Narrow paper not blocking

sensor in center of path

1. Remove and reinsert paper.

2. Center paper

Printer prints blank paper

1. Paper inserted upside-down

2. Wrong side of roll coated

3. Printout positioned outside

printable area by “set”

command

1. Invert paper roll

2. Invert roll as test, have paper

made properly

3. Change “set” command

settings to relocate printout

Print quality poor

1. Print density set too low

2. Printhead not fully lowered

3. Incorrect paper type for XPM

80™ printhead

1. Adjust print density, other burn

time adjustments.

2. Lower printhead.

3. Procure and use correct paper.

Baud rate, or other

configuration setting

changes not effective after

use of Configuration Tool

1. Printer was not reset after

changes made with

Configuration Tool.

1. Reset printer. Consider

enabling “Automatically reset

printer” option on “Tool

Settings” tab of XPM 80™

Configuration Tool.

10. Maintenance

The XPM 80™ printers require very little maintenance.

Note:

Discharge your body’s static electric charge by touching a grounded surface before

performing any maintenance procedure. Do not touch the connector pins of the printhead

cable with your bare hands.

Note:

Do not touch the surface of the thermal printhead. Mechanical stress or shock

(including foreign contamination) to the surface of the printhead substrate should be avoided

to prevent printhead damage.

Cleaning the XPM 80™ Printer

Clean the XPM 80™ whenever it becomes dusty, as paper dust will reduce the friction of the platen

and cause the print quality to deteriorate.

Open the print mechanism by using the Printer Access Control.

Remove any paper

, if

necessary.

Clean the platen with a special platen cleaning agent and a lint-free cloth. DO NOT use

alcohol to clean the platen because alcohol hardens the platen material.

Gently wipe the surface of the thermal printhead using a cotton pad soaked in

METHANOL to remove dust on the heating elements. DO NOT use sandpaper or other

abrasives.

Dry the XPM 80™ mechanism completely and reload the paper.

Note:

Condensation should be avoided. If condensation occurs, do not power the printer until

all condensation has dissipated.