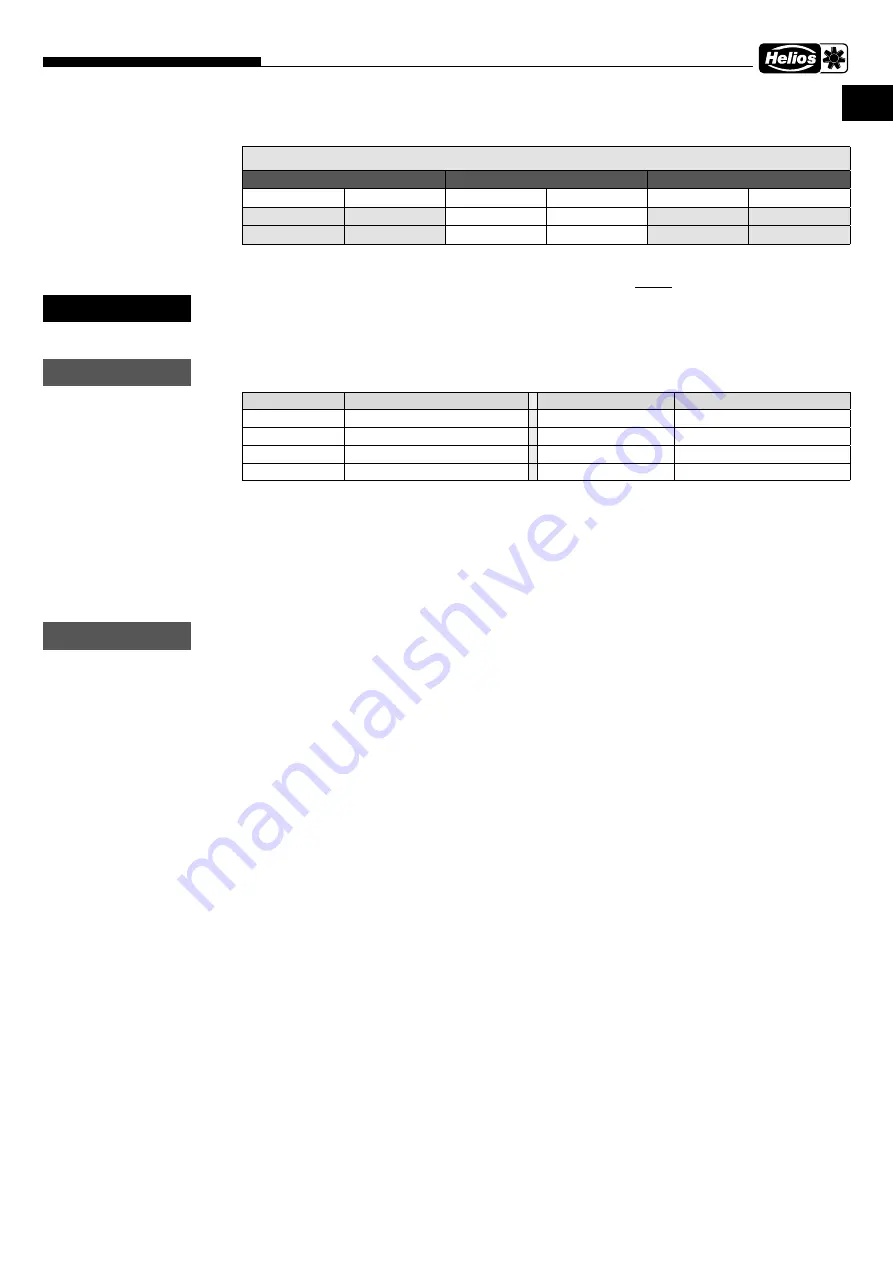

3 .6 Maximum permissible vibration limits pursuant to ISO 14694 / ISO 10816-3

– Installation of a vibration monitoring system

in explosion-proof version (on site)

The installation of a vibration monitoring system must be carried out on the outside of the fan casing.

The air gap (see Fig .7) must not be affected by the installation of the vibration monitoring system!

3 .7 Recommended tightening torque for mounting screws

The following tightening torques for mounting screw and nut connections (strength class 8.8) must be used:

The impeller fastening to the motor shaft is secured against loosening with thread-locking fluid in the factory .

3 .8 Functional safety - Emergency operation

When using the fan in important technical supply function, the system must be designed in such a way that automatic

emergency operation is guaranteed in case of a fan failure. Suitable solutions include e.g. parallel operation of two less

powerful units with a separate electric circuit, standby fan, alarm devices and emergency ventilation systems.

3 .9 Electrical connection

Before any maintenance or installation work or before opening the terminal compartment, the device must be

fully isolated from the power supply and secured against unintended restart!

– The regulations for avoiding an ignition hazard due to electrostatic discharges (TRGS 727) must be implemented.

– The electrical connection must only be carried out by a qualified electrician in accordance with the data in the termi-

nal box and enclosed wiring diagrams.

– The relevant standards, safety regulations (e.g. DIN VDE 0100) and technical connection conditions of the electricity

supply companies must be strictly observed.

– An all-pole mains switch / isolator switch with a contact opening of at least 3 mm (VDE 0700 T1 7.12.2 / EN 60335-

1) is mandatory.

– Every motor must have a

motor protection device

of category II (2)G, see Directive 2014/34/EU (Product

Safety Act), which must be adjusted to the rated current of the motor and trip within the time tE specified on the

motor type plate, provided the motor is blocked. The function must be tested on the basis of the tripping charac-

teristic line enclosed with the protection switch. Also observe the regulations especially enclosed with the device.

– Electrical connection data must correspond to the motor type plate data.

– The installation of the power cable is to be carried out professionally! The introduction of the connecting cable into

the fan must compensate the movement by the vibration dampers. The connecting cable must not touch sharp

objects.

– Only explosion-proof cable glands must be used for cable entries and connections!

– Three-phase current types must be connected by interchanging two phases for counter-clockwise rotation in the

clockwise rotating field.

– Safety components, e.g. protection grilles, must not be dismantled, bypassed or disabled.

– For further operations see the following section “Commissioning”.

– Earth connections, including any supplementary equipotential bonding, must be properly installed!

3 .10 Commissioning

The following checks must be carried out before initial commissioning:

– Check that fan operation corresponds with intended purpose

– Compare power supply voltage with rating plate data

– Check fan for solid mounting and professional electrical installation

– Check all parts especially screws, nuts and protection grilles for tight fit. Do not loosen screws in the process!

– Check unhindered movement of impeller and minimum air gap

– Check that direction of rotation and air flow direction correspond. Check direction of rotation of impeller (by acti-

vating for a short time; wear protective goggles when checking the direction of rotation)

– Compare power consumption with rating plate data

– Test functionality of motor protection device

– Test protective conductor connection

– Check sealing of the connection cable and tight clamping of cable wires

– Commissioning may only take place if protection against contact is guaranteed

Max. permissible vibration limits for fan output < 75 kW

Commissioning

Alarm

Deactivation

Firmly mounted Flexible installation Firmly mounted Flexible installation Firmly mounted Flexible installation

[mm/s]

[mm/s]

[mm/s]

[mm/s]

[mm/s]

[mm/s]

4 .5

6 .3

7 .1

11 .8

9 .0

12 .5

WARNING

m

ATTENTION

m

Screw size

Tightening torque

VERBUS RIPP

Tightening torque

M8

20 Nm

M8

25 Nm

M10

35 Nm

M10

49 Nm

M12

60 Nm

M12

86 Nm

M16

150 Nm

M16

210 Nm

ATTENTION

m

7

MegaBox MB

– Centrifugal fans

Installation and Operating Instructions

EN

Summary of Contents for MegaBox MB

Page 15: ...13 MegaBox MB Radialventilatoren Montage und Betriebsvorschrift DE...

Page 29: ...13 MegaBox MB Centrifugal fans Installation and Operating Instructions EN...

Page 30: ...14 MegaBox MB Centrifugal fans Installation and Operating Instructions EN...

Page 31: ...15 MegaBox MB Centrifugal fans Installation and Operating Instructions EN...