4

Electrical pre-heater AIR1-EVH RH

Installation and Operating Instructions

+40 °C). Damages due to improper transportation, storage or commissioning must be verified and are not liable for

warranty.

2 .0 .3 Shipping

The shipping must be carried out carefully. It is recommended to leave the unit in the original packaging until installation

to avoid possible damages and contamination.

The shipping must be carried out by trained and experienced personnel and the necessary safety precautions should

be taken to prevent overturning and slipping of the device. it should be ensured that the weight is evenly distributed

when shipping the unit.

m

Personal injury and/or material damage due to incorrect shipping!

It must be ensured that the means of transport/lifting is suitable to accommodate to the required weight and size

capacity.

– Make sure that the unit is firmly seated before lifting it.

Material damage due to excessive load!

Before off-loading the units, please ensure that the means of transport/lifting have sufficient capacity for the required

weight.

m

Risk of personal injury and material damage!

The package units may have an eccentric centre of gravity . If the package unit is incorrectly lifted, it can tip

over . Falling or tipping package units can cause serious personal injury .

When lifting, the centre of gravity of the package unit must be vertically beneath the crane hook .

2 .0 .4 Disassembly and re-assembly

m

Danger to life due to electric shock!

An electric shock can result in death or serious injury.

– Ensure that the unit is voltage-free and isolated from the mains power supply. Ground and short circuit the unit, shield

neighbouring live components.

– The unit must be isolated from the mains power supply before disassembly or re-assembly.

m

Risk of personal injury and material damage!

The disassembly and re-assembly of the unit are not part of routine maintenance.

– The disassembly and re-assembly of the unit may only be carried out by qualified specialist personnel.

Risk of material damage when installing heating and cooling registers!

The following must be taken into account when installing heating and cooling registers:

– Close all hydraulic stop valves.

– Isolate all connections and ensure that the unit is leak-free with regard to oil and refrigerants.

– Since the diameter of the heating and cooling pipes is small, water may remain in the register after emptying. For

safety reasons, compressed air should be blown through the system to remove the remaining water.

2 .0 .5 Disposal

m

Danger to life due to electric shock

!

An electric shock can result in death or serious injury.

– Ensure that the unit is voltage-free and isolated from the mains power supply. Ground and short circuit the unit, shield

neighbouring live components.

Dispose of all components and filters and disused operating materials (e.g. refrigerants) in an environmentally-friendly

manner in accordance with the local codes, practices and environmental regulations.

An authorised specialist waste processing company must dispose of the unit or the individual components. The appo-

inted contractor must ensure that the components are separated according to material types.

2 .1 Mechanical assembly

m

Danger to life due to electric shock!

The installation and connection of the unit may only be carried out by qualified specialist personnel. The electrical con-

nections must be carried out by a person who has proper professional training and experience in the relevant accident

prevention regulations, as well as other generally recognised safety and occupational health codes, with authorisation

to perform work on the unit.

Risk of injury due to electric shock, moving parts (fans) and hot surfaces .

Electrical pre-heater

The unit must be fully isolated from the mains power supply before all maintenance and installation work and

opening the terminal compartment! The electrical connections must be carried out in accordance with the fol-

lowing wiring diagrams and must only be carried out by qualified electricians . The electrical connection must

be fully isolated until the final assembly!

The electrical pre-heater is only suitable for installation outside in combination with the matching weather pro-

tection cover and an outside air intake hood!

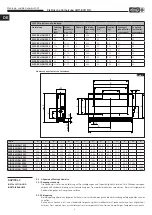

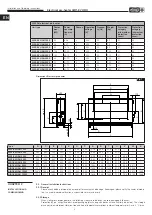

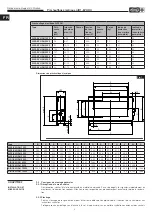

Assembly area

The assembly position must ensure protection against reaching into the heating register. E.g. this is possible using

ducts or the outside air intake hood.

When installing the unit, the following criteria must be observed when installing the unit to ensure easy accessibility for

maintenance and maintenance work (Fig. 2).

m

DANGER

ATTENTION

m

DANGER

m

DANGER

m

WARNING

ATTENTION

m

DANGER

m

DANGER

m

DANGER

EN