OPERATION

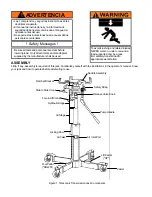

Priming Instructions (refer to Figure 2)

1. Tilt the entire tranmission jack over two casters so that the pump and handle are below the hydraulic cylinder as

shown in Figure 2.

2. Open the release valve knob "COUNTERCLOCKWISE" and pump handle until "resistance" is felt.

3. Close the release valve "clockwise" and continue pumping while restoring the jack to its upright position

The transmission saddle assembly is raised and lowered by means of an air operated stage and a hydraulic stage. A

locking pawl automatically engages at the end of the air cylinder travel to mechanically lock the cylinder and prevent

drop when the transmission is loaded onto the saddle assembly.

Transmission Removal

1. With vehicle elevated on lift, position the jack under transmission to be removed.

2. Connect 1/4" air nipple to air inlet port. Connect air hose to the air nipple. Depress the lift pedal that marked

"UP"

and

raise air stage to its fully extended position. The air stage will stop automatically by the locking pawl at its full height. Air

hose can be removed.

3. Close the release valve by turning the release valve knob in clockwise direction. Pump the handle until saddle reached

desired position

4. Make sure saddles are centered and positioned directly under the transmission to be removed.

5. Adjust the position of the saddle assembly side to side and tilt forward or backward to get a firm contact at the bottom of

transmission.

6. Slowly pump the handle with a small strokes so the saddle assembly raised slowly to contact with the transmission.

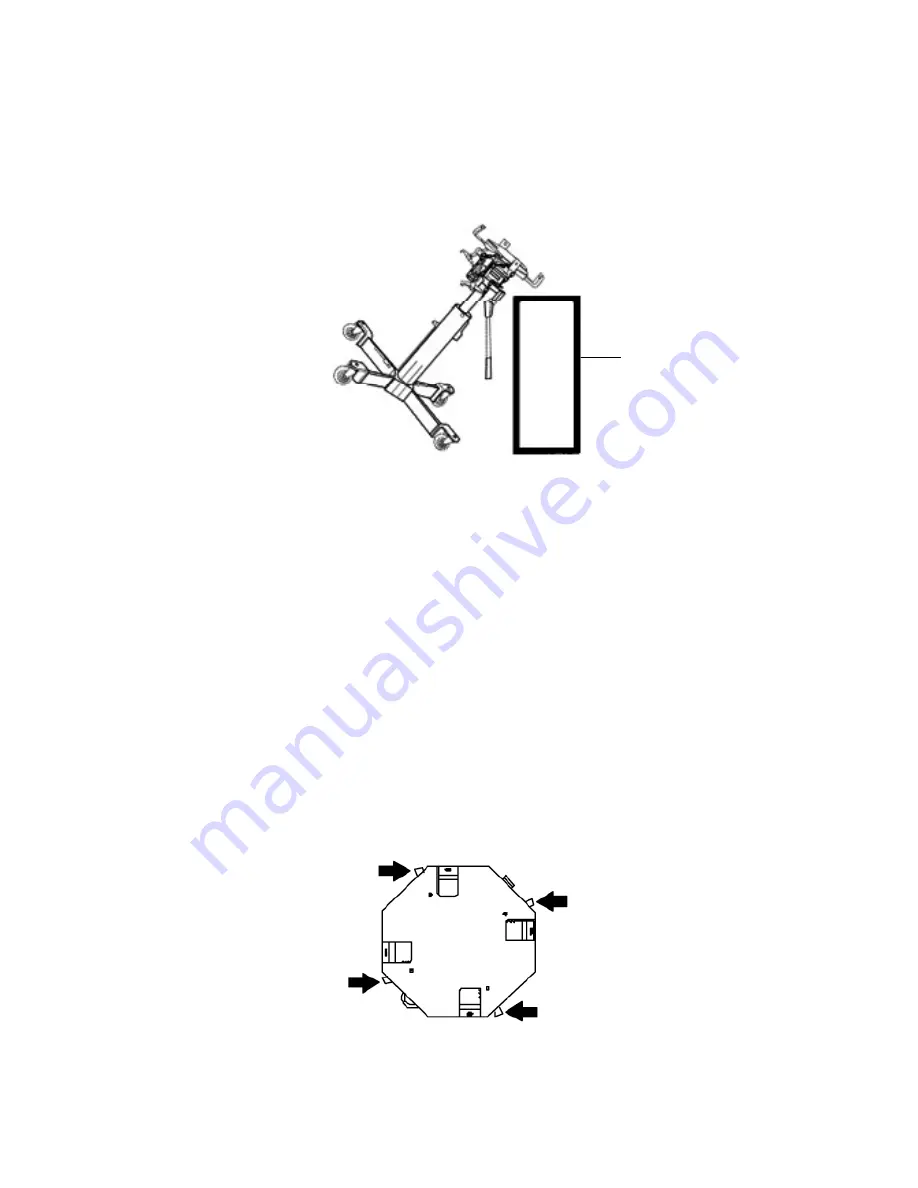

7. Push in the 4 ratchet brackets on saddle assembly firmly to grab the edges of transmission housing. (see Figure 3)

Figure 2

Unlock pawls to pull out

ratchet brackets.

Figure 3

Supporting

Station