Heat & Glo • 350TSI-P-CEM • 2033-973 Rev. G • 4/17

16

B. Maintenance Tasks-Qualified Service

Technician

To prevent inadvertent burner operation while servicing

this appliance:

• Unplug DC regulator from junction box.

• Remove batteries from battery pack (if installed).

• Shut off gas supply to the appliance.

The

following tasks must be performed by a qualified ser

-

vice technician.

Gasket Seal and Glass Assembly Inspection

Frequency:

Annually

By:

Qualified Service Technician

Tools needed:

Protective gloves, drop cloth and a stable

work surface.

• Inspect gasket seal and its condition.

• Inspect fixed glass assembly for scratches and nicks that

can lead to breakage when exposed to heat.

• Confirm there is no damage to glass or glass frame.

Replace as necessary.

• Verify that fixed glass assembly is properly retained and

attachment components are intact and not damaged.

Replace as necessary.

Firebox

Frequency:

Annually

By:

Qualified Service Technician

Tools needed:

Protective gloves, sandpaper, steel wool,

cloths, mineral spirits, primer and touch-up paint.

• Inspect for paint condition, warped surfaces, corrosion

or perforation. Sand and repaint as necessary.

• Replace fireplace if firebox has been perforated.

Control Compartment and Firebox Top

Frequency:

Annually

By:

Qualified Service Technician

Tools needed:

Protective gloves, vacuum cleaner, dust

cloths

• Vacuum and wipe out dust, cobwebs, debris or pet hair.

Use caution when cleaning these areas. Screw tips that

have penetrated the sheet metal are sharp and should

be avoided.

• Remove all foreign objects.

• Verify unobstructed air circulation.

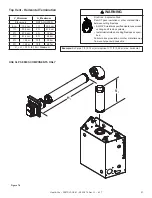

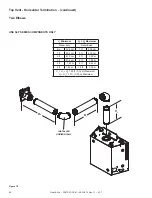

Gas Pressure Information

Frequency:

Upon initial installation and gas valve re

-

placement or service.

By:

Qualified Service Technician

Tools needed:

Protective gloves, manometer, flashlight,

screw driver set.

• Gas pressure taps are accessible by removing the deco

-

rative front and fixed glass assembly. Refer to section

11.A for information related to the gas valve and gas

pressure settings.