UK

Disc-Roller 2,5 - 3,0 – 3,5 - 4,0 m (1-section) 12/08-2014

17

Maintenance and service

A.

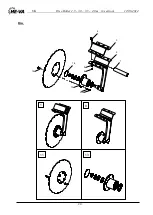

Grease hubs at the discs so that grease is appearing at the seals of the hubs.

Every 30 hours of operation grease again. If the machine is driving under difficult

conditions (much dust), grease more often.

Important:

B.

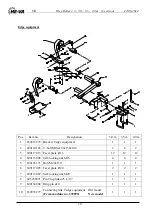

After 10 hours of operation, retighten wheels, bearings and stop rings. Check hydraulic

hoses, fittings and cylinders for leaks and retighten.

C.

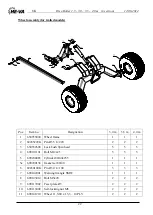

Every 10 hours of operation, grease all pivoting points in side sections, drawbar and wheel

assembly.

D.

After end season, grease and wash machine.

Important:

Oil, type Hydro Texaco HD 32 has been

filled in the hydraulic system.

Grease hubs at the discs before wash,

to avoid water penetration into the bearings.

Grease piston rods.

Summary of Contents for Disc Roller 2,5m

Page 2: ......

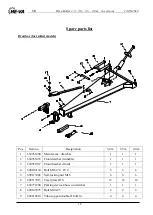

Page 36: ...UK Disc Roller 2 5 3 0 3 5 4 0 m 1 section 12 08 2014 36 Spring Board 2 5m 3 0m 3 5 m...

Page 37: ...UK Disc Roller 2 5 3 0 3 5 4 0 m 1 section 12 08 2014 37 Spring Board left 4 0m...

Page 40: ...UK Disc Roller 2 5 3 0 3 5 4 0 m 1 section 12 08 2014 40 El depth stop for disc...

Page 45: ...UK Disc Roller 2 5 3 0 3 5 4 0 m 1 section 12 08 2014 45 Air brakes...

Page 57: ...UK Disc Roller 2 5 3 0 3 5 4 0 m 1 section 12 08 2014 57 Diagrams El depth stop...

Page 58: ...UK Disc Roller 2 5 3 0 3 5 4 0 m 1 section 12 08 2014 58 Lights...

Page 60: ...The design is subject to modification without notice...