1.34

1.34

MAINTENANCE

Every 50 Hours

Perform routine checks:

Refer to

DAILY

BEFORE USE

.

Check power unit wheel nut torque:

Wheel nut

torque setting - 80 Nm (60lbs ft)

Rotary attachment:

Inspect the chain couplings

between the cutter headgear boxes. Inspect sprock-

et teeth and chains for signs or wear.

IMPORTANT: PREVENT DAMAGE

- If the

chains / countershaft are removed for any reason,

ensure that the cutterhead phasing is correct after

refitting.

Lubrication

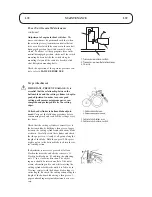

Transaxle:

Check oil level on dipstick. This

should be level with the hole indicator on the dip-

stick. Top up if necessary with the correct grade of

transmission fluid, refer to

SPECIFICATIONS

.

Top up fluid should be introduced through the dip-

stick tube.

Cutterhead Gearbox (Rotary Attachment):

Remove filler plug on top of the gearbox and

check oil level. Gearbox should be 3/4 full. If nec-

essary top up with the correct grade of oil, refer to

SPECIFICATIONS

.

General:

Lightly apply a good quality general

purpose lubricating oil to the following points;

All linkage pivot points

All inner cables

Rear roller quadrant pivot bushes (Verge

Attachment).

Apply a good quality medium grade grease to the

following points:

Front wheels (Rotary Attachments).

Carrier pivot (Verge Attachments).

Cylinder bearing housings (Verge Attachments).

Chain couplings - between cutterhead gearboxes

(Rotary Attachment).

Summary of Contents for CONDOR 510D

Page 2: ......

Page 4: ......

Page 49: ...1 49 1 49 NOTES ...

Page 50: ...1 50 1 50 NOTES ...

Page 52: ......