03/21

Model SP158.15

Page 5 of 8

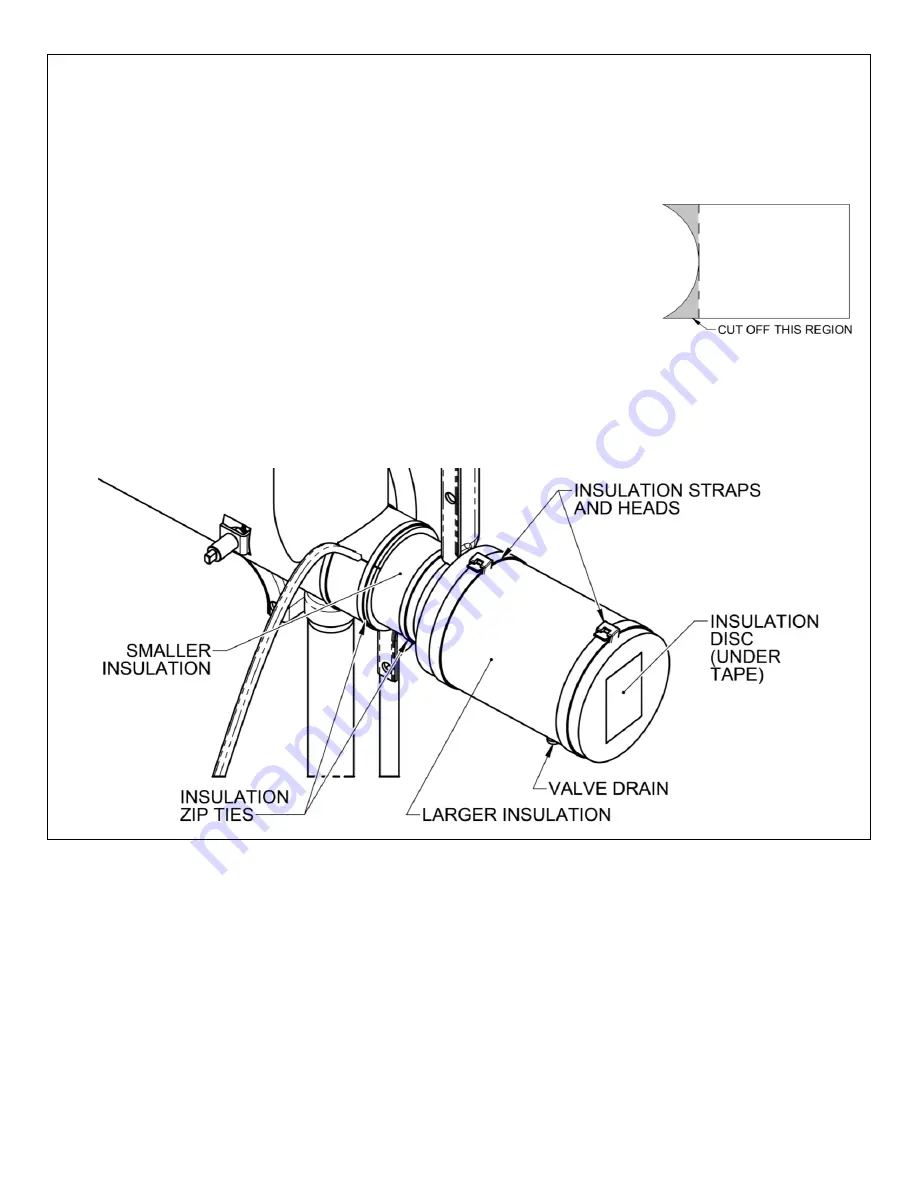

STEP 5: Insulation

a) Place the smaller insulation ring around the bare auxiliary piping within the jacketing, using both the

integral adhesive strips on the insulation to close it up. Be sure this new piece is butted fully against the

factory insulation. Use the insulation zip ties (found in a bundle of 4) to secure the new piece, and to

replace the ones previously cut. Tighten each zip tie only enough to close the insulation around the piping.

b) Note the large radius found on one end of the larger insulation. For this

application, carefully cut the radiused portion away with a serrated knife or

saw. Do not cut off any more than is necessary. Place the insulation around

the freeze valve assembly, noting the opening for the freeze valve drain.

c) Place the new insulation disc into the open end of the larger insulation. Apply

the seam tape over it to hold it in place.

d) Use both the integral adhesive strips on the larger insulation to close it up.

Use the insulation straps and heads on the two ends of the larger insulation to

further hold it in place

– only tighten the straps enough to close the insulation

around the plumbing (and insulation disc).

e) If the insulation is to be exposed to severe levels of UV (e.g. a rooftop installation), consider applying a

protective coating or cladding (such as K-FLEX 374 or K-FLEX Clad) to the insulation.

f) If desired, connect the valve drain to a drain line.