42

4000364740

E12.16

USA / GB

H14TX - HB40 - H16TPX - HB44J

C

- Maintenance

Periodic inspection

In addition to the daily inspection program

Visual inspection without disassembly

To check by test

Visual inspection with small disassembly or

movement needed to reach the part.

Replacement is necessary.

Levelling

Proof tests. Need HAULOTTE Services®

authorization. For countries where machines are

not subject to controlled periodic maintenance.

Functional adjustments / Checks

Yes

No

Corrected

Not applicable

Manuals and displays. Clean or replace if necessary.

Presence, cleanliness and legibility of the

manufacturer's plate

Control box

Operation of emergency lowering device

Work Platform. Floor, guardrails, access and extensions

No cracks, broken weld, paint chipped

No deterioration and visible damage

Harness anchor points are not cracked or

damaged, with the decal attached and legible

No screws missing / loose parts

Entry bar/gate closes automatically and is not

prevented from closing.

Locking in closed position of folding guard-rail

(if equipped)

Work platform, floor, guardrails, access and extensions

No cracks, broken weld, paint chipped

No foreign body in joints or slides

Entry bar/gate closes automatically and is not

prevented from closing

Locking in closed position of folding guard-rail

(if equipped)

State of extension desk fastening

Lift assembly (jib, boom, mast, arm, turret)

Summary of Contents for H14TX

Page 2: ...2 4000364740 E12 16 USA GB H14TX HB40 H16TPX HB44J...

Page 14: ...14 4000364740 E12 16 USA GB H14TX HB40 H16TPX HB44J A Safety precautions Notes...

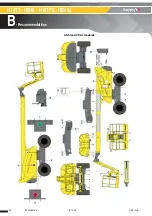

Page 21: ...A B C D E F G H I 21 4000364740 E12 16 USA GB H14TX HB40 H16TPX HB44J B Recommendations Notes...

Page 25: ...A B C D E F G H I 25 4000364740 E12 16 USA GB H14TX HB40 H16TPX HB44J B Recommendations Notes...

Page 26: ...26 4000364740 E12 16 USA GB H14TX HB40 H16TPX HB44J B Recommendations EAC standard...

Page 29: ...A B C D E F G H I 29 4000364740 E12 16 USA GB H14TX HB40 H16TPX HB44J B Recommendations Notes...

Page 30: ...30 4000364740 E12 16 USA GB H14TX HB40 H16TPX HB44J B Recommendations ANSI and CSA standards...

Page 60: ...60 4000364740 E12 16 USA GB H14TX HB40 H16TPX HB44J C Maintenance Notes...

Page 62: ...62 4000364740 E12 16 USA GB Control Filling up Oil tank E001 15 min Notes...

Page 64: ...64 4000364740 E12 16 USA GB Control Oil change Wheel reducer E002 15 mn Notes...

Page 66: ...66 4000364740 E12 16 USA GB Replacement Hydraulic filter cartridge E003 15 min Notes...

Page 68: ...68 4000364740 E12 16 USA GB Filling up Oil change Fuel tank E004 15 mn Notes...

Page 76: ...76 4000364740 E12 16 USA GB Replacement Tightening Wheel E006 15 min Notes...

Page 78: ...78 4000364740 E12 16 USA GB Tightening Screws bolts and nuts E007 15 min Notes...

Page 80: ...80 4000364740 E12 16 USA GB Control Oil change Turntable rotation gearbox E008 15 mn Notes...

Page 86: ...86 4000364740 E12 16 USA GB Control Filling up Battery charge Battery E018 10 min Notes...

Page 88: ...88 4000364740 E12 16 USA GB Lubrication Telescope E022 15 mn Notes...

Page 92: ...92 4000364740 E12 16 USA GB H14TX HB40 H16TPX HB44J D Diagnosis assistance Notes...

Page 102: ...102 4000364740 E12 16 USA GB H14TX HB40 H16TPX HB44J E Electric circuit Notes...

Page 104: ...104 4000364740 E12 16 USA GB H14TX HB40 H16TPX HB44J F Hydraulic circuit Notes...

Page 112: ...2 Electrical diagram H14TX HB40 H16TPX HB44J 1 2 STATION SELECTION...

Page 113: ...3 Electrical diagram H14TX HB40 H16TPX HB44J 1 3 INPUT OUTPUT CALCULAT0R I...

Page 114: ...4 Electrical diagram H14TX HB40 H16TPX HB44J 1 4 INPUT OUTPUT CALCULAT0R II...

Page 115: ...5 Electrical diagram H14TX HB40 H16TPX HB44J 1 5 JOYSTICKS...

Page 116: ...6 Electrical diagram H14TX HB40 H16TPX HB44J 1 6 OPTIONS...

Page 117: ...7 Electrical diagram H14TX HB40 H16TPX HB44J 1 7 OPTIONS...

Page 118: ...8 Electrical diagram H14TX HB40 H16TPX HB44J 1 8 OPTIONS...

Page 119: ...1 Hydraulic diagram H14TX HB40 H16TPX HB44J 1 H14TX HB40 1 1 FOLIO 1 1...

Page 120: ...2 Hydraulic diagram H14TX HB40 H16TPX HB44J 2 H16TPX HB44J 2 1 FOLIO 1 1...