Page 18

BCS3000M-9

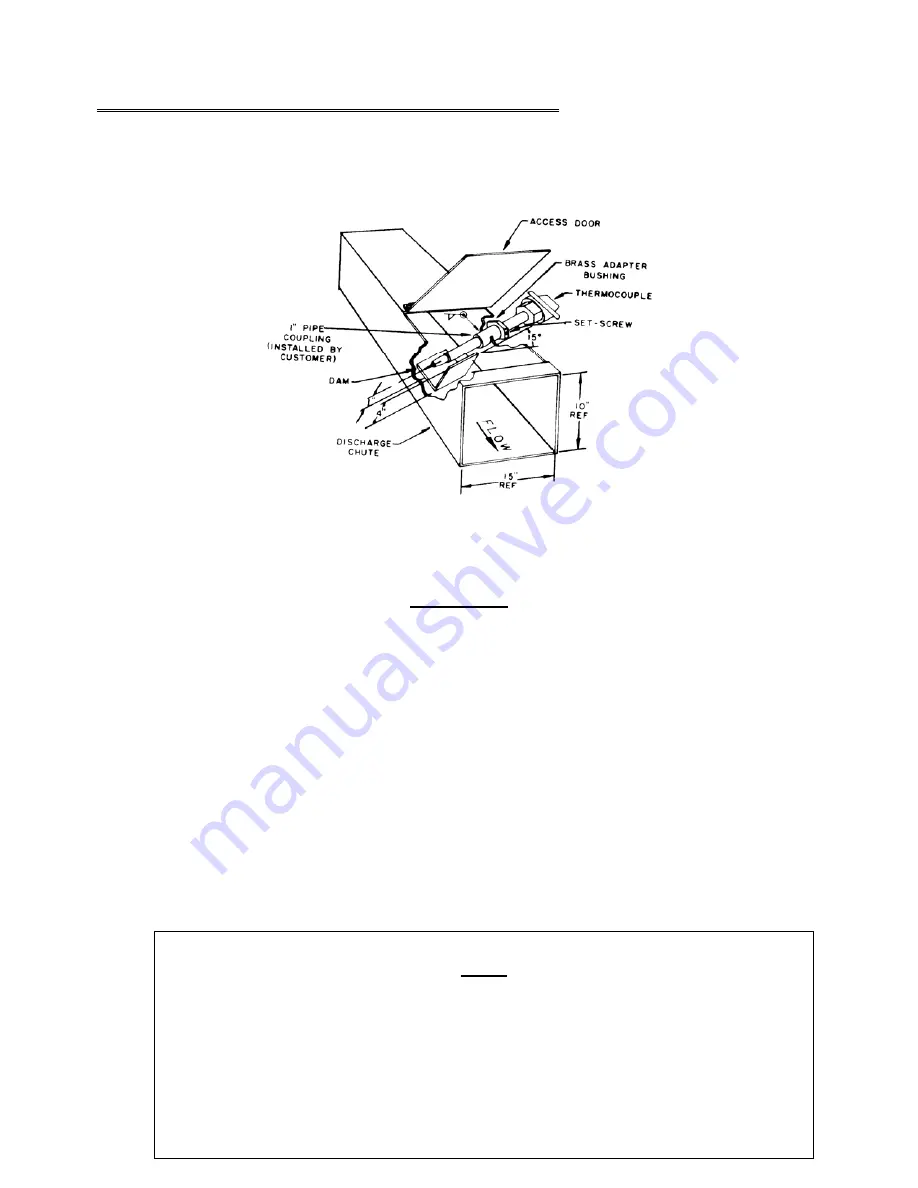

APPENDIX F: MATERIAL THERMOCOUPLE INSTALLATION

Install a Hauck Rapid Response Material Temperature Thermocouple in the material discharge

chute to sense the temperature of the material leaving the dryer. Wire the thermocouple to the

proper terminals in the panel.

Drawing showing the placement of the

thermocouple and "dam" in the dryer discharge chute.

IMPORTANT

A small clearance (1" maximum) should be provided under the thermocouple so material

will not be trapped between the thermocouple and the chute. Trapped material will cause a

heat loss path and the thermocouple will give erroneous readings.

The thermocouple should make good contact with the material but not be subject to severe

abrasion caused by high velocities. If the material is moving so fast that it bounces and

leaves air adjacent to the thermocouple, the temperature it senses will be lower than the

material. It may be necessary to place a dam in the chute so that the thermocouple is in a

relatively slow moving area next to the dam. The dam must only be wide enough and high

enough to create a localized area of build-up where the material loses velocity BUT DOES

NOT STOP FLOWING. The thermocouple must not be located in a stagnant zone or

erroneous temperature readings will result. Because of the large number of variables

involved, it is impossible to set down any exact size or location of the dam that will always

work. Field experimentation will be necessary if good results are to be obtained. It is

advisable to tack weld the dam in place so that it can be easily modified if it fails to perform

satisfactorily.

NOTE

During normal operation, the thermocouple should be rotated once a month to expose

a different area of its surface to the abrasive forces of the material. This procedure will

increase the effective life of the thermocouple. If excessive wear occurs, a protective

tube may be added to shield the shaft in the region of the high velocity flow.

Thermocouple cables must be separated from AC power and control wiring to

avoid interference and nuisance shutdowns. Observe polarity when making

thermocouple connections. Regardless of TC type, the red wire is always

negative.