MAINTENANCE

Form No. MDWM-0311

9

General

The Hatco Mini Display Warmer is designed for maximum

durability and performance, with minimum maintenance.

ELECTRIC SHOCK HAzARD:

• Turn OFF power switch, unplug power cord, and allow

unit to cool before performing any cleaning,

adjustments, or maintenance.

• DO NOT submerge or saturate with water. Unit is not

waterproof. Do not operate if unit has been submerged

or saturated with water.

• Do not steam clean or use excessive water on unit.

• This unit is not “jet-proof” construction. Do not use jet-

clean spray to clean this unit.

• Do not clean unit when it is energized or hot.

This unit has no “user-serviceable” parts. If service is

required on this unit, contact an Authorized Hatco Service

Agent or contact the Hatco Service Department at

800-558-0607 or 414-671-6350; fax 800-690-2966; or

International fax 414-671-3976.

Cleaning

To preserve the finish of the Mini Display Warmer, perform the

following cleaning procedure daily.

Use non-abrasive cleaners only. Abrasive cleaners could

scratch the finish of the unit, marring its appearance and

making it susceptible to soil accumulation.

1. Turn off the unit, unplug the power cord, and allow the unit

to cool.

2. Remove and wash all food pans.

3. Wipe down all interior and exterior metal surfaces with a

damp cloth. Stubborn stains may be removed with a good

non-abrasive cleaner. Clean hard to reach areas using a

small brush and mild soap.

4. Clean the glass side panels and door panel(s) using ordinary

glass cleaner and a damp, soft cloth or paper towel. The

side panels are removable for detailed cleaning, if

necessary. Refer to the “Removing a Glass Panel”

procedure in this section for removal.

WARNING

NOTICE

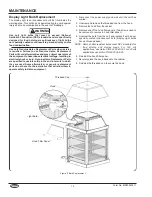

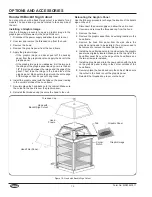

Removing a Glass Panel

1. While holding the glass panel securely, remove the screws

holding one of the glass brackets to the unit.

2. Carefully lift the glass panel off the unit and set in a safe

place with the screws.

Installing a Glass Panel

1. Slide the glass panel into the groove of the installed glass

bracket.

2. While holding the glass panel securely, reinstall the

removed glass bracket to the unit.

Figure 8. Glass Panel Removal

Screw

Glass Bracket

Glass Panel

Summary of Contents for MDX-1X

Page 14: ...NOTES Form No MDWM 0311 14 ...

Page 15: ...NOTES Form No MDWM 0311 15 ...