TO ADJUST THE TIMING OF THE NEEDLE

AND THE LOWER LOOPER

Correct Setting:

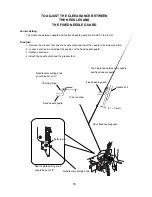

When the needle comes up 2.8 to 3.2 mm (7/64 to 1/8”) from its lowest position, the tip of the

lower looper comes just left of the needle (#11) on the right.

To adjust:

1. Remove the presser foot, needle plate and left-side needle.

2. Replace right-side needle with a #11 one.

3. Turn the handwheel toward you to get the lowest needle position.

4. Set the two guages (787-G02, 787-G03), as shown in (Fig. 1) and tighten bolt (B).

# This time, there should be no clearance between the gauges and the needle bar lower

bushing.

5. Remove plate gauge (787 - G03). Then turn the handwheel toward you until it touches the needle

bar lower bushing, as shown in (Fig. 2).

6. In this condition, loosen the hexagonal bolt (C) just enough to move the lower looper base.

Adjust the lower looper position in order to meet the tip of lower looper with left-side of needle

(#11), as shown in (Fig. 3) and (Fig. 4).

Tighten hexagonal bolt (C).

7. Remove the gauge (787 - G02).

# Check the clearance between the needle and lower looper.

# Check the clearance between the loopers.

8. Replace the right side needle with a #14 one.

9. Attach the needle, needle plate and presser foot.

# Be careful not to tighten bolt (B) too much.

787-G03

Needle bar lower bushing

Bolt (B)

Needle gauge

(787-G02)

(Thickness: 3 mm

Color: Black)

Plate gauge (787-G03)

No clearance !!

R a i s e t h e

needle bar

(Fig. 2)

Right needle (#11)

3 mm

Lower looper

(Fig. 4)

(Fig. 1)

(Fig. 3)

Lower looper

Lower looper base

Hexagonal bolt (C)

Right needle (#11)

19

Summary of Contents for 9002D

Page 1: ...SERVICING MANUAL 9002D ...