12

Super-Magnum Coal Stoker Stove

Do Not Burn Wet Coal!

3-90-02702R6_03/13

D. The Chimney

This unit must be installed into a chimney approved for use

with solid-fuel appliances. In the U.S., it must be connected to

(1) a prefabricated chimney complying with the requirements

for Type HT chimneys in the Standard for Chimneys, Factory-

Built, Residential Type and Building Heating Appliances, UL

103, or (2) a code-approved masonry chimney with a flue

liner.

In Canada, this unit is listed for use with prefabricated

chimneys tested and listed to the high temperature (650

degrees C) chimney standard, ULC S-629, or with a code

approved masonry chimney.

For mobile homes, (US only) it must only be installed with

prefabricated chimney systems, including the installation

components, tested to use in mobile homes; the diameter

should match the diameter of the flue collar opening

The minimum recommended height for any chimney is 16

ft. (4.8 m) above flue collar height. For non-mobile home

installations, a round flue (either masonry or approved

prefabricated), of either 6" (150 mm), 7" (180 mm) or 8"

(200 mm) may be used. For square or rectangular masonry

chimneys, nominal sizes of 8" x 8" or 8" x 12" (200mm x 200

mm, 200 mm x 300 mm) may be used.

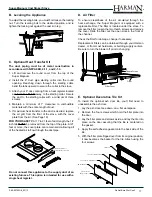

Codes require that solid-fuel chimneys extend 3 ft. (0.9 m)

above the highest point at which they exit from the roof. Then,

the chimney must extend 2 ft. (6 m) above the highest point

within a 10 ft (3 m) radius. Thus, the 3 foot, 2 foot, 10 foot

rule:

3ft.

- Above roof exit point

2ft.

- Higher than anything within-

10ft.

of the chimney.

NOTE

: The restriction of not venting more than one appliance

to the same flue applies to the

U.S.

specifically. While it is not

recommended that you use the same chimney for more than

one appliance, in

Canada

certain exceptions may be made.

Be sure to contact your building code inspection official to

see if this option is allowed in your area, and to find out the

specific requirements for such an installation.

Do not connect this unit to a chimney flue servicing

another appliance.

AN APPROVED CANADIAN

WALL PASS-THROUGH

Hole with a minimum

clearance of 18" (450 mm)

between connector and wall.

Non-combustible cover, one

side only. If two covers are

used, each must be mounted

on non-combustible spacers

at least 7/8" (21mm) away

from the wall.

1" (25mm)

Clearance

AN APPROVED U.S.

WALL PASS-THROUGH

Closest

Combustible

Material

Minimum 2" (50mm)

Clearance to Brick

Minimum 12"

(300mm) to Brick

Liner

Fire Clay

Thimble

Chimney

Connector

Chimney Flue

Masonry Chimney Built to

NFPA 211 Specifications.

Minimum 12" (300mm)

to Combustibles

More Than 10 ft. (3m)

10 ft. (3m)

Ridge

Chimney

2 ft. (0.6m) min.

Height Necessary

Above Any Roof Sur-

face Within 10ft. (3m)

3ft. (0.9m)

minimum

above

exit

point

The 3-foot, 2-foot, 10 foot rule