4 - Sprayer setup

46

Liquid System

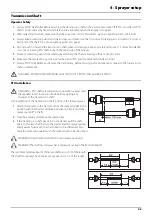

Pulsation Damper

The air pressure in the pulsation damper is factory preset at 2 bar to

cover spray working pressures between 3 and 15 bar.

When using spray pressures outside this range, the air pressure

should be adjusted as shown in the diagram. The diagram is

embossed on the damper.

Before Putting the Sprayer into Operation

Although the sprayer has been supplied with a strong and protective surface treatment on steel parts, bolts etc. in the

factory, it is recommended to apply a film of anti-corrosion oil (e.g. CASTROL RUSTILO or SHELL ENSIS FLUID) on all metal

parts in order to avoid chemicals and fertilizers discolouring the enamel.

If this is done before the sprayer is put into operation for the first time, it will always be easy to clean the sprayer and keep

the enamel clean for many years. This treatment should be carried out every time the protection film is washed off.

Spray pressure (Bar)

Damper pressure (Bar)

1.5 - 3

0 - 1

3 - 15

1 - 3

15 - 25

3 - 4