20

HARDI

®

GAS ENGINE ESTATE SPRAYER OPERATOR’S MANUAL

7.1 Cleaning The Sprayer (cont.)

Be familiar with local legislation regarding disposal of agricultural

chemicals, mandatory decontamination methods, etc. Contact the

appropriate office, e.g. Department of Agriculture.

Cleaning starts with calibration as a well calibrated sprayer will ensure

the minimal amount of remaining spray liquid. It is a good practice to

clean the sprayer immediately after use thereby rendering the sprayer

safe and ready for the next application. This also prolongs the life of

the components.

It is sometimes necessary to leave the spray liquid in the tank for short

periods of time (e.g. overnight), or until the weather becomes suitable

for spraying again. Unauthorized persons and animals must not have

access to the sprayer under these circumstances.

Cleaning

1. Dilute the remaining spray liquid in the tank with at least 10 parts

water and spray the liquid out into the field or lawn you have just

sprayed.

2. Select and use the appropriate protective clothing. Select detergent

suitable for cleaning and suitable deactivation agents if necessary.

3. Rinse and clean sprayer and tractor externally. Use detergent if

necessary.

4. Remove all filters and clean them. Be careful not to damage the

mesh. Replace filters when the sprayer is completely clean.

5. With the pump running, rinse the inside of the tank. Remember the

tank roof. Rinse and operate all components and any equipment that

has been in contact with the chemical.

6. After spraying the liquid out again in the field or lawn, stop the pump

and fill at least 1/5 of the tank with clean water. Note that some

chemicals require the tank to be completely filled. Add appropriate

detergent and/or deactivating agent, e.g. Washing soda or Triple

ammonia.

NOTE:

If a cleaning procedure is given on the chemical label, follow it

closely.

7. Start the pump and operate all controls enabling the liquid to come

in contact with all the components. Leave the distribution valves until

last. Some detergents and deactivating agents work best if left in the

tank for a short period. Check the label.

Summary of Contents for ES 50

Page 1: ...ESTATE SPRAYERS GAS ENGINE Operator s Manual 67301103 6 01 ...

Page 2: ......

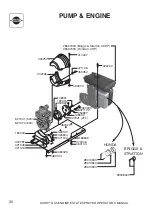

Page 30: ...28 HARDI GAS ENGINE ESTATE SPRAYER OPERATOR S MANUAL 11 0 PARTS DRAWINGS 500 PUMP ...

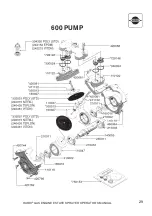

Page 31: ...29 HARDI GAS ENGINE ESTATE SPRAYER OPERATOR S MANUAL 600 PUMP ...

Page 33: ...31 HARDI GAS ENGINE ESTATE SPRAYER OPERATOR S MANUAL PUMP FITTINGS ...

Page 34: ...32 HARDI GAS ENGINE ESTATE SPRAYER OPERATOR S MANUAL ET MANUAL CONTROL ...

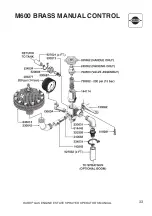

Page 35: ...33 HARDI GAS ENGINE ESTATE SPRAYER OPERATOR S MANUAL M600 BRASS MANUAL CONTROL ...

Page 36: ...34 HARDI GAS ENGINE ESTATE SPRAYER OPERATOR S MANUAL ES 50 80 TANK ...

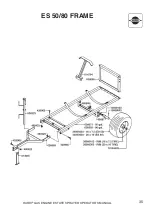

Page 37: ...35 HARDI GAS ENGINE ESTATE SPRAYER OPERATOR S MANUAL ES 50 80 FRAME ...

Page 38: ...36 HARDI GAS ENGINE ESTATE SPRAYER OPERATOR S MANUAL SM 50 80 TANK FRAME ...

Page 40: ...38 HARDI GAS ENGINE ESTATE SPRAYER OPERATOR S MANUAL 14 HD BOOM ...

Page 41: ...39 HARDI GAS ENGINE ESTATE SPRAYER OPERATOR S MANUAL SPRAYGUN ...

Page 42: ...40 HARDI GAS ENGINE ESTATE SPRAYER OPERATOR S MANUAL HOSE REEL ...

Page 45: ...43 HARDI GAS ENGINE ESTATE SPRAYER OPERATOR S MANUAL 13 0 NOTES ...

Page 46: ...44 HARDI GAS ENGINE ESTATE SPRAYER OPERATOR S MANUAL NOTES ...

Page 47: ......