Troubleshooting Guide:

Condition Reason

Method

of

Adjustment

Fabric is not feeding.

Insufficient Foot

Controller pressure.

Increase pressure on

Foot Controller.

Needle breaks.

Needle not inserted properly.

Fabric being pulled too fast.

Loose Needle Set Screw.

Insert Needle correctly or

replace with correct Needle.

Do not pull fabric by hand.

Use hand only to guide fabric.

Tighten Set Screw firmly.

Thread breaks.

Incorrect threading.

Bent or damaged Needle.

Thread tension too tight.

Thread tangled.

Needle inserted incorrectly.

Thread machine correctly.

Replace Needle.

Adjust tension.

Thread correctly.

Insert Needle correctly.

Stitches skip.

Bent Needle or Needle

point damage.

Needle set loosely.

Incorrect threading.

Wrong Needle used.

Insufficient Foot

Controller pressure.

Replace Needle.

Set Needle firmly in position.

Thread machine correctly.

Use correct Needle.

Increase pressure on

Foot Controller.

Stitches are irregular.

Thread tension not balanced.

Adjust tension.

Fabric puckers.

Thread tension too tight.

Threading incorrect or tangled.

Differential Feed Dial at

wrong ratio.

Adjust tension.

Rethread machine.

Set value of Differential Feed

Dial at 0.7-N.

Machine does not operate.

Power Cord Plug not connected.

Connect Power Cord Plug to a

120 volt, grounded, electrical

receptacle.

SKU 91500

PAGE 19

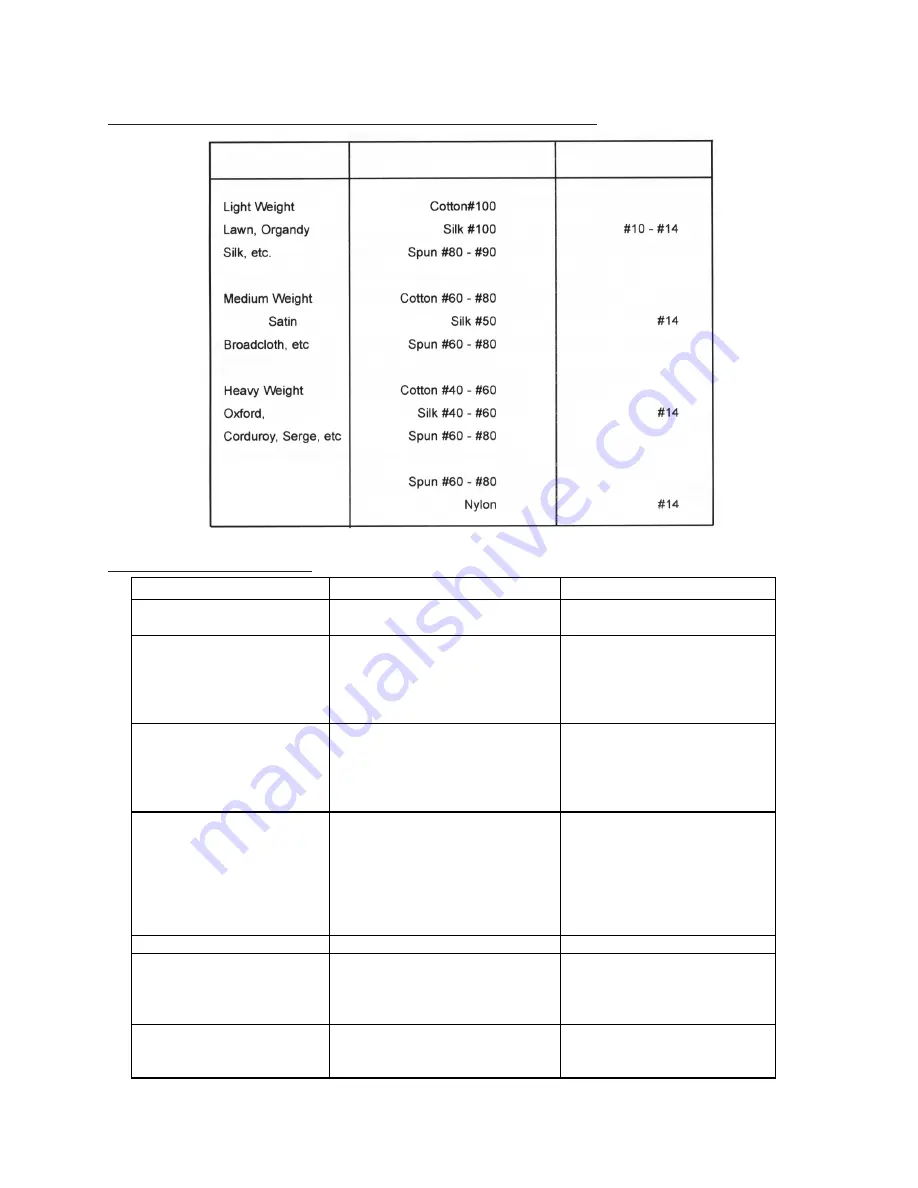

Thread And Needle Suggestions For Certain Cloth Types:

Muslin,

Denim

Knit

Wool (woven, knit)

Cloth

Thread

Needle