5

PREPARATION

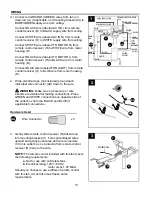

HARDWARE CONTENTS

(shown actual size)

Before beginning assembly of product, make sure all parts are present. Place motor on carpet or on

foam to avoid damage to finish. Compare parts with package contents list and hardware contents list. If

any part is missing or damaged, do not attempt to install, operate or assemble the product.

Estimated Assembly Time:

120

minutes

Tools Required for Assembly (not included):

Electrical Tape, Phillips Screwdriver, Pliers, Safety Glasses,

Stepladder and Wire Strippers

Helpful Tools (not included):

AC Tester Light, Tape Measure, Do-It-Yourself Wiring Handbook and Wire

Cutters

Wire

Connector

Qty. 9

AA

Motor

Screw/Washer

Qty. 7

BB