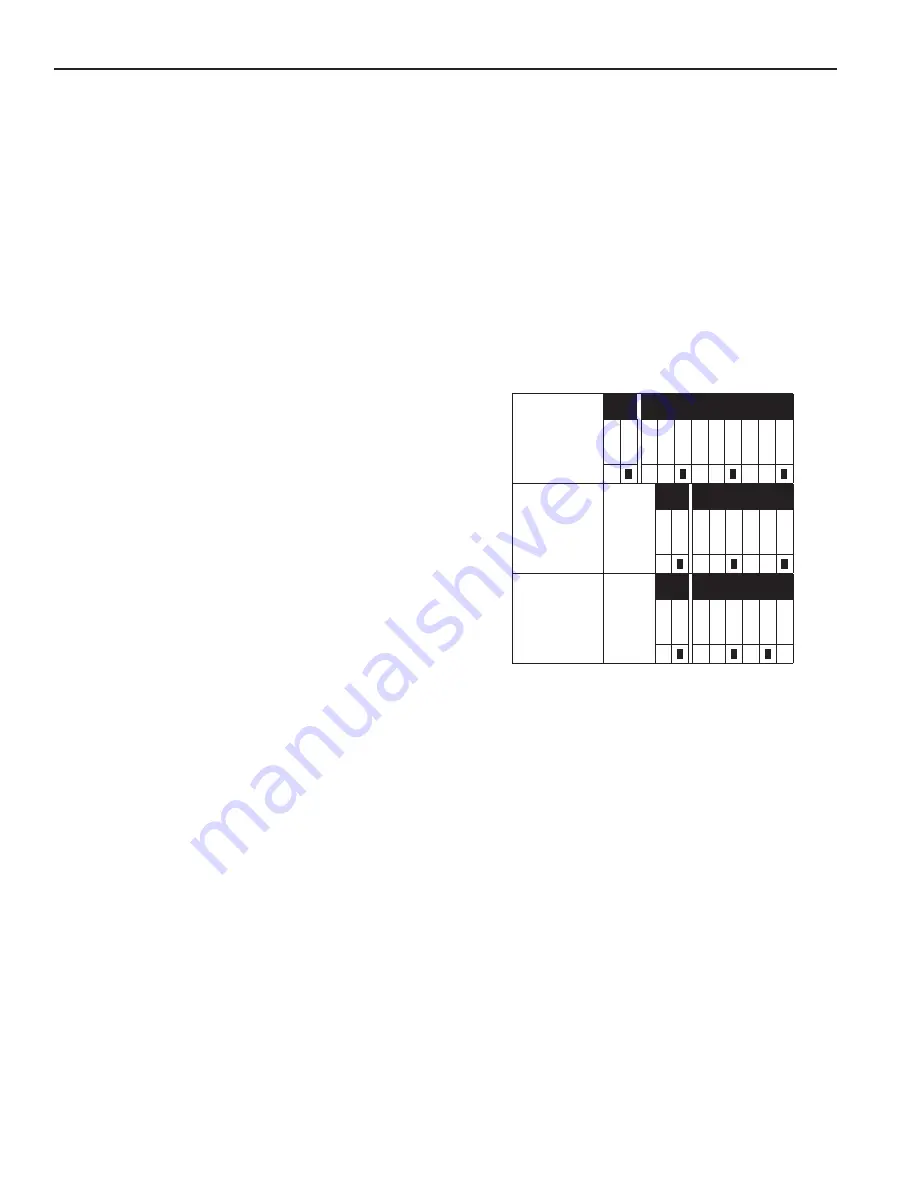

PXVC - (PT)

PXVC - T

PXVC - (All

other models)

FIGURE 3.

AO1

UI3

UI1

UI2

0...10V

0...20mA

0...10V

0...10V

0...20mA

0...20mA

0...20mA

0...10V

RT or contact

RT or contact

RT or contact

AO1

UI2

UI1

0...10V

0...20mA

0...20mA

0...20mA

RT or contact

RT or contact

RT or contact

0...10V

AO1

UI2

UI1

0...10V

0...20mA

0...20mA

0...20mA

RT or contact

RT or contact

RT or contact

0...10V

4

PXVC

AUGUST 2018

INSTALLATION:

The PXVC model controllers require careful attention to

the wiring diagrams based on the application to prevent

damage to the equipment. Failure to follow the diagrams

as presented may result in damage to the controller and

voidance of product warranty.

Review the controller specific applications and select the

application based upon your controller and application

needs for additional applications contact factory. Motorized

Control Valve Applications are available in bulletin R649b

WIRING NOTES

(refer to controller specific applications

for detailed diagrams):

The controller power pins 1 and 2 accepts 24 volts DC, refer

to Hansen drawing Figure 2 for reference.

INPUTS / OUTPUTS

Digital Output #1 is set up for pulse width operation and

requiring a 24-250VAC 3A power source. The output acts

as a switch, stopping and starting the valve (pins 3 and 4)

Digital Output #2 is setup to be the user alarms and requires

a 24-250VAC 3VA power source. The output acts as a switch,

stopping and starting the electricity flow (pins 5 and 6)

The analog output control signal does not require a power

source and should be connected directly to the Motorized

Control Valve as shown in Figure 2 (pins 7 and 8)

Universal Input #1 must be setup to properly and when

used as an analog (4-20mA) input a 24VDC power source

must be applied to the sensor as indicated in the diagrams

(pins 11 and 12)

(Excludes PXVC-PT) Universal Input #2 must be a continuous

circuit (switch closed) to operate as a remote interlock pins

(13 and 14).

SENSOR INSTALLATION:

Pressure Transducers

– Hansen recommends all pressure

transducers to be installed into a gauge valve which is

installed into the pressure port. This line of controller

is designed to work with transducers with a 4-20mA

signal. Pressure transducers are imprecise below -60F,

and standoffs are recommended. It is important that the

pressure transducer is installed as close to the outlet of

the heat exchanger (evaporator, shell and tube, plate and

frame, etc.) as possible to attain a precise reading.

Temperature Sensors

– Sensor should be installed as

close to the pressure sensing element as possible (where

applicable), or the outlet of the heat exchanger. Thermal

compound should be used to ensure sensor lag is kept to

a minimum. Immersion wells are highly recommended for

all applications.

Superheat / Temperature Applications

– When attempting

to read saturated vapor, intermittent liquid contacting the

sensing element will result in unstable sensor readings,

causing system instability. When operating a system where

liquid is present an immersion well should be used for

precise measurement. The well should be installed so

that it is constantly immersed in the liquid. Plumbing traps

are necessary to stabilize the flow of liquid and reduce

imprecision in the measurement. This is crucial for all

applications dependent on temperature measurements for

liquid or superheat control. Sensors should be installed per

wiring diagrams and as shown on the pipe at the 4’oclock

or 8’clock position as shown in Figure 5. For DX evaporator

setup, and the entire length of the pipe must be insulated.

Other Sensors

– Refer to the sensorproduct bulletin

(Pressure and Temp Sensor (HPT) bulletin PT100c,

Techni-Level probes P109, Vari-Level Probes P112)

SETTING UP THE CONTROLLER:

1. Verify jumpers on back of controller are set as follows:

2. Connect sensors and power. In superheat applications.

The pressure and temperature sensors should be placed

as close to one another as possible.

3. (Optional) Configure user desired alarms. Alarms close

the circuit between pins 4 and 6, and may be linked to

any device with a power rating between 24 - 250VAC

and 3A Max Current.

4. (Optional) Connect remote interlock. Interlock is active

when switch is closed and deactivated when switch is

open.

5. Best practice is to test function the unit, verifying output

matches expectations, using a process calibrator (4-

20mA by default) measuring analog signal output.

6. Switch off power

7. Connect outputs to valves and place into service

Contact Hansen if errors are encountered

PXVC UNIVERSAL CONTROLER