Page 4

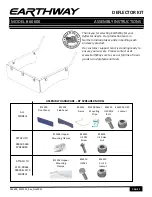

ASSEMBLY INSTRUCTIONS

1

2

Attach the leg support to the chair legs(B1 & B2) by using the 1/4"x20 mm bolts and washers as shown in

.

Guide these bolts through the holes in the leg support into pre-drilled holes in the chair legs.

.

Fig 1

Hand tighten only

.

,

Attach the support bar to the chair legs by using the 1/4"x20 mm bolts and washers as shown in

. Guide these

bolts through the holes in the support bar into the pre-drilled holes in the chair legs.

.

Fig 2

Hand tighten only

.

,

3

At this time make any adjustments to alignment of all parts. Tighten all bolts a few revolutions at a time, alternating

between bolts until tightened.

.

Do not over tighten. Over tightening may strip bolts

J

E K

D

B2

B1

E

K

FOOT CAP

C

Fig. 1

Fig. 2

J

4

5

Set the chair frame on the rocker assembly with front of the seat facing you and the arrows on the "U" bar pointing

towards you as shown in

. This is very important for a safe, balanced rocking motion.

.

Fig 3

If chair frame has been

properly positioned on the rocker assembly, all arrows on the "U" bar and rocker assembly will be pointing

in the same direction.

Critical Step: The "U" metal plates must be installed in the proper location.

Fig 4

Fig 5 Hand tighten only.

Adjust alignment of the holes of support bar and "U" bar Insert a "U" metal plate as shown in

. Then

guide the 5/16"x40 mm bolts through the holes in the "U" metal plate “U” bar, rocker plate and bottom of the “U”

metal plate. Add a Ø8.0 x 2.3 mm spring washer and a nut to each bolt as shown in

.

Repeat the same procedure on the other side.

Read this step and carefully

examine.

.

.

,

,

.

H

A

Fig. 3

FOOT CAP

Fig. 4

Fig. 5

ROCKER PLATE

"U" BAR

ROCKER

ASSEMBLY

"U" BAR

L

L

F

G

I