21

20

TEMPERATURE CALIBRATION PROCEDURE

(for technical personnel only)

The meter is factory calibrated for temperature. It is recommended

that the following procedure is performed by authorized technical

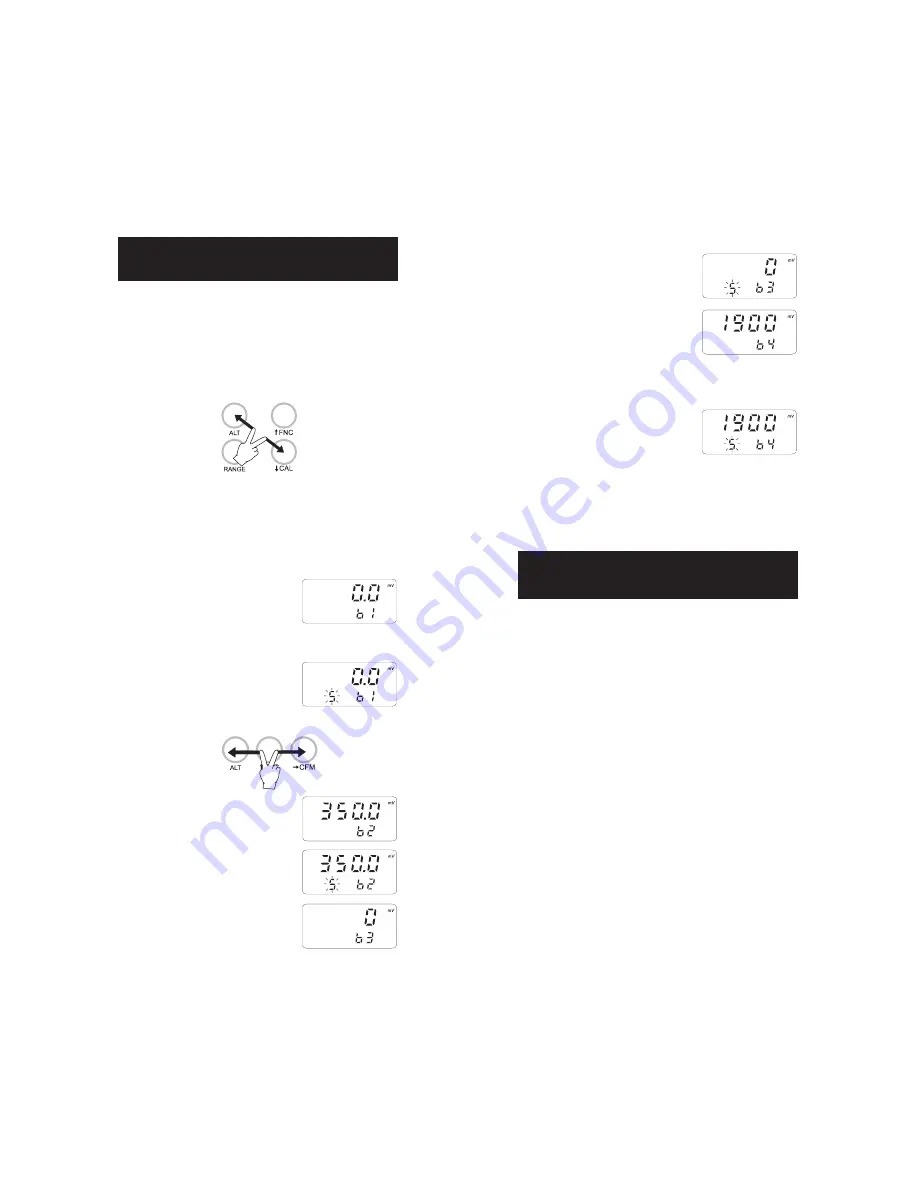

personnel only.

A two point calibration at 0.0, 25.0°C (32.0, 77.0°F) or 0.0, 50.0°C

(32.0, 122.0°F) has to be performed in order to store the new

calibration data in memory.

1. Immerse the electrode with the built-in temperature sensor in the

0°C (32°F) temperature bath.

2. Press RANGE until temperature reading is selected.

3. Press ALT and CAL to enter temperature calibration mode.

4. Enter the password if requested.

5. When the reading is stable the "S" symbol starts to blink.

6. Press ALT and CFM to confirm. LCD will display 50.0°C (122.0°F)

as the following calibration point.

7. If 25.0°C (77.0°F) is desired as second point, press to display

25.0°C (77.0°F).

8. Immerse the probe in the second temperature bath.

9. When the reading is stable, the "S" symbol starts to blink.

10. Press ALT and CFM to confirm and return to temperature reading

mode.

mV CALIBRATION PROCEDURE

(H I 9 82 4 0 ONL Y )

A 4 point calibration must be performed. The first two calibration

points are 0 and 350 mV for low range calibration; the other two

points are 0 and 350 or 1900 mV for high range calibration.

1. Connect a mV simulator (

HI 8427

or

HI 931001

with the proper

connection cable) to the meter and set it to 0 mV.

2. Press ALT and CAL when LCD is displaying mV.

3. User is prompted to enter password if it has been set to a value

different from 0000, otherwise skip to step 6.

4. Enter the password with the arrow keys.

5. Press ALT and CFM to confirm the password or ALT and CAL to

return to normal operational mode.

6. If password is correct or not set, the

meter will display "0.0 mV" on the upper

LCD and "b1" on the lower; if wrong, it

will return to normal operational mode

without any message.

7. When the "S" symbol blinks in the lower

LCD, the reading is stable and calibra-

tion can be confirmed.

8. Press ALT and CFM to confirm the first value.

9. The meter will display "350.0 mV" in the

upper LCD and "b2" on the lower one.

10. Set the simulator to +350 mV.

11. When the "S" symbol blinks in the lower

LCD, the reading is stable. Press ALT and

CFM to confirm the second value.

12. The meter will display "0 mV" in the

upper LCD and "b3" on the lower one.

13. Set the simulator to 0 mV.

14. When the "S" symbol blinks in the lower

LCD, the reading is stable. Press ALT and

CFM to confirm the third value.

15. The meter will display "350 mV" in the

upper LCD and "b4" on the lower one.

Pressing the " " key, 1900 mV will be

selected as calibration point.

Note:

+1900 mV is suggested as the last calibration point to

obtain the best accuracy throughout the entire mV range.

16. Set the simulator to +1900 mV.

17. When the "S" symbol blinks in the lower

LCD, the reading is stable. Press ALT

and CFM to confirm the fourth value.

18. Calibration is now complete and the instrument returns to normal

operational mode.

Note:

"Err" message notifies the user if the selected value is wrong.