15

Hangar 9 P-47D-40 Thunderbolt 30cc ARF

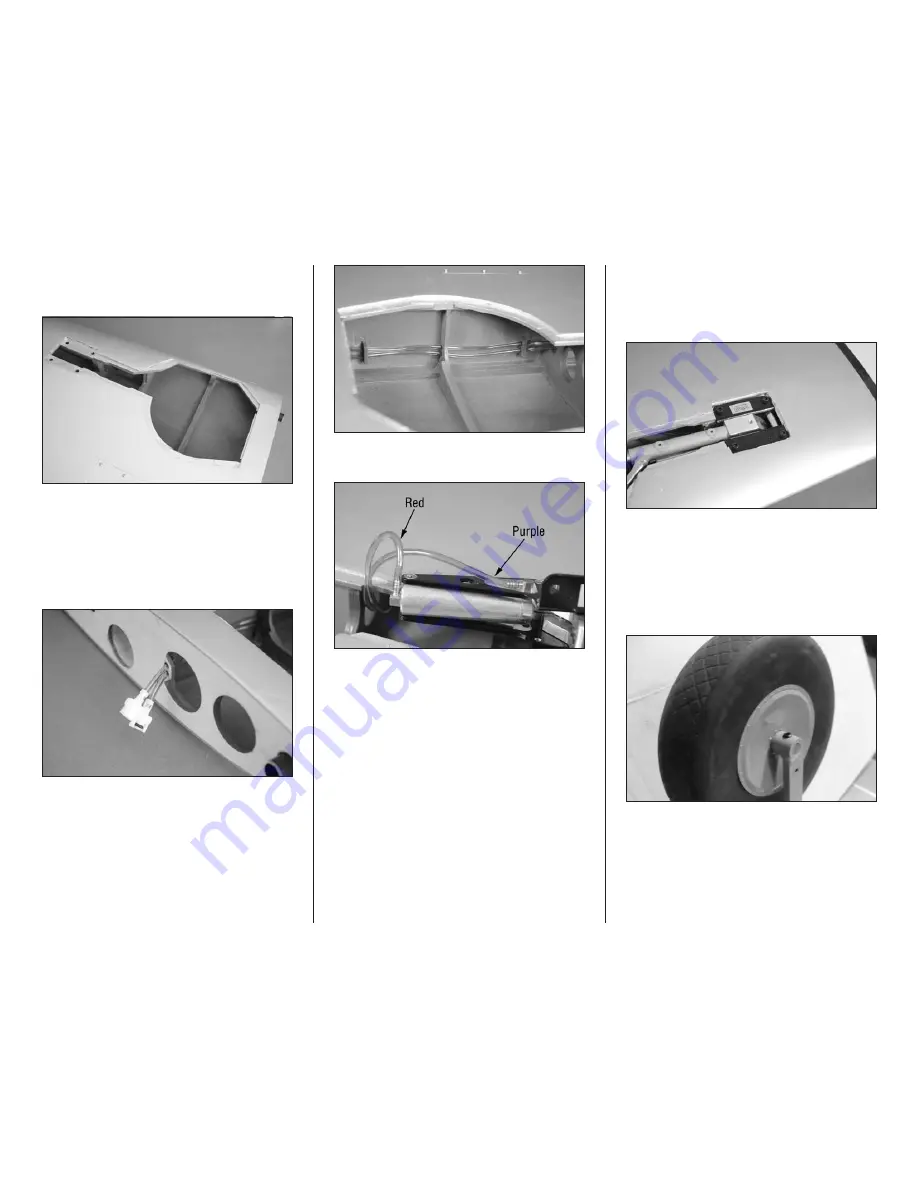

2. Use a hobby knife and #11 blade to remove the

covering from the retract opening. Use a trim seal tool to

iron the covering around the edge of the opening.

3. Cut a piece of red and purple air line to a length

of 15 inches (381mm). Place a quick disconnect on each

line. Make sure to use one connector with the O-ring and

one without to avoid connecting the lines incorrectly.

Guide the air lines through the openings in the wing from

the root to the retract mount. Fittings have been installed

to route the air line so it doesn’t interfere when the

retracts are in the UP position.

4. Attach the air lines to the retract. Note the

orientation of the lines and how they are connected.

Before securing the main gear, we recommend

running a 6/32 x 1-inch socket head screw with a

7/64-inch hex wrench through each of the blind

nuts to remove any paint that may have entered the

blind nut during the assembly of your model.

5. Secure the retract mechanism in the wing using four

6-32 x 1-inch socket head cap screws and a 7/64-inch hex

wrench. The scissor link will face toward the leading edge

of the wing. Make sure to use threadlock on the screws to

prevent them from vibrating loose.

6. Enlarge the hole in the wheel using a drill and

1/4-inch (6mm) drill bit. Secure the wheel to the retract

mechanism using the axle and setscrew provided with the

retract. Use a rotary tool and cutoff wheel to trim the axle so

it is flush with the retract strut. Use a flat file to make a flat

area for the setscrew to tighten to so the axle won’t come

loose. Also use threadlock on the setscrew before tightening

it with a 3/32-inch hex wrench.