28

Hangar 9 F4U-1D Corsair 50 ARF

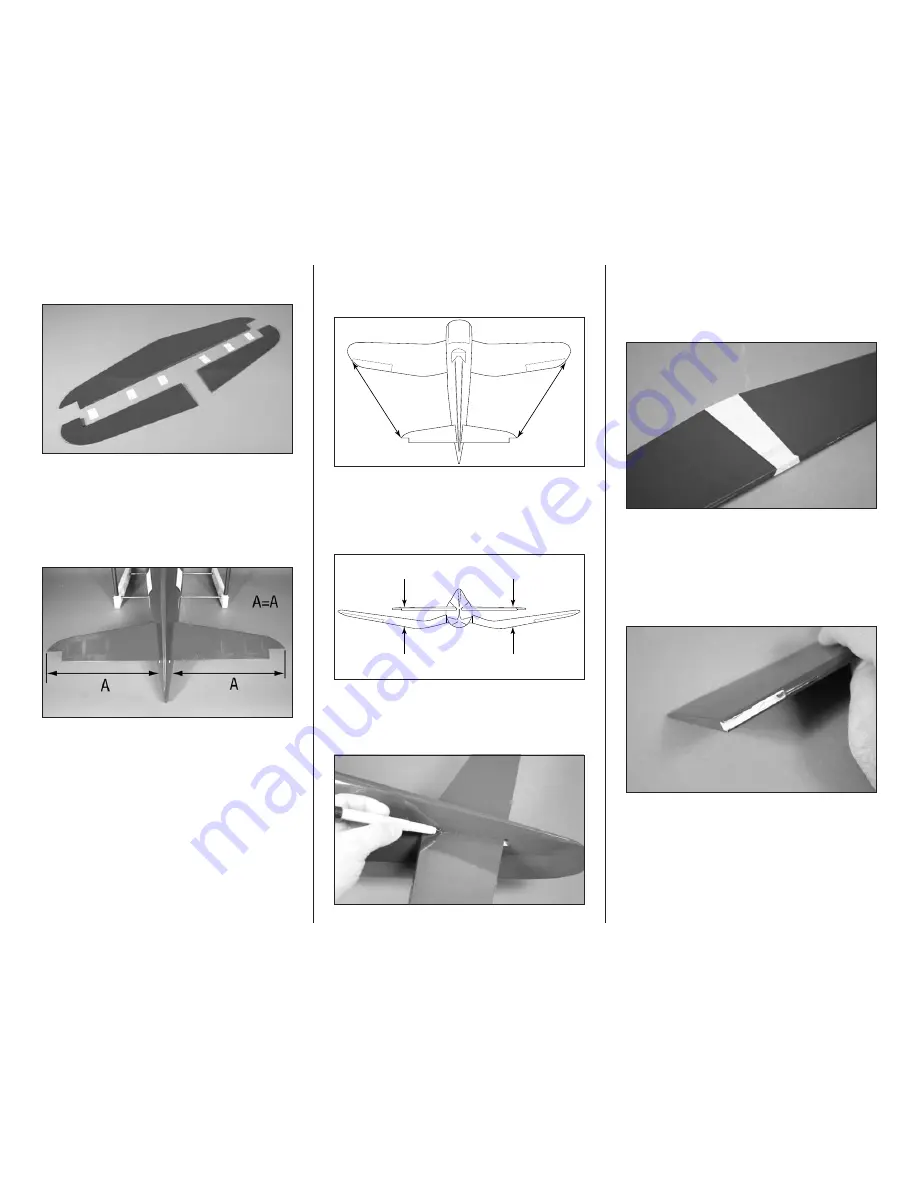

2. Separate the elevators from the stabilizer. Set the

elevators and six CA hinges aside.

3. Determine the top and bottom of the stabilizer by

inspecting the covering seam. The top covering overlaps

down, around and over the bottom covering. Slide the

stabilizer into the slot in the fuselage with the stabilizer as far

forward in the slot as possible, measure from the fuselage to

each tip. Center the stabilizer so the measurements are the

same.

6. Measure from stabilizer tip to the wing tip on both the

left and right side of the airframe. The measurement must

match exactly to align the stabilizer with the wing.

A

A

A=A

7. Stand back 8–10 feet (2–3 meters) and view the

aircraft from the rear. The wing and stabilizer must be an

equal distance from each other to be in alignment. If not,

use medium grit sandpaper to lightly sand the opening in the

fuselage to correct any alignment issues.

Check alignment

8. Double check the alignment of the stabilizer as

described in steps 5 through 7. Once set, use a felt-tipped

pen to trace the outline of the fuselage on the top and

bottom of the stabilizer.

9. Remove the stabilizer from the fuselage. Use a hobby

knife and a new #11 blade to trim the covering 1/16-inch

(1.5mm) inside the lines drawn in the previous step.

Remove the covering, exposing the wood at the center of the

stabilizer.

Note

: Make sure to use a new #11 blade and

use light pressure to trim only the covering.

Avoid cutting into the underlying wood, which

could weaken the structure of your model.

10. Use a hobby knife with a #11 blade to remove the

covering from the elevators for the 3mm metal joiner rod.