29

Hangar 9 Alpha 40 ARF Assembly Manual

Step 12

Repeat Steps 10 and 11 to install the second screw.

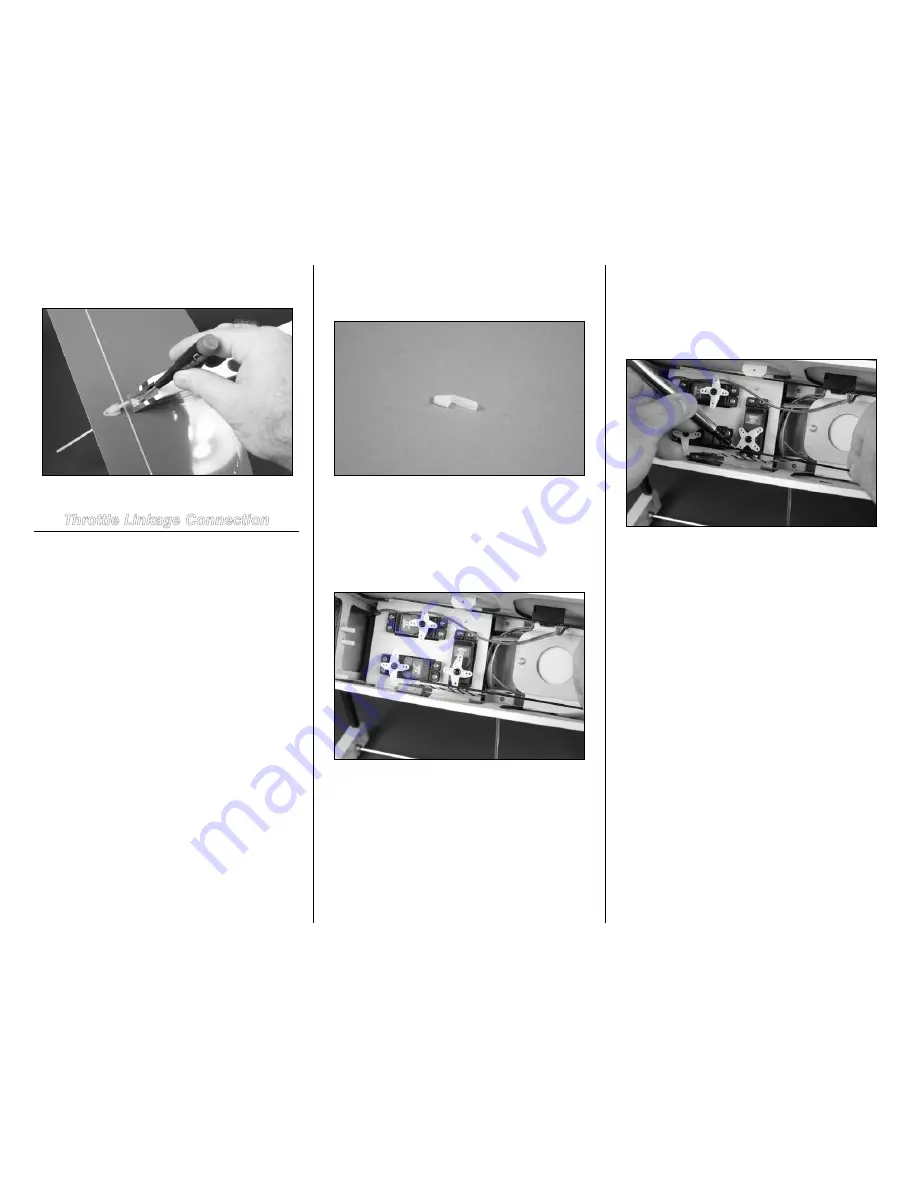

Throttle Linkage Connection

Required Parts

Fuselage

Pushrod snap link

Transmitter

Required Tools and Adhesives

Pliers

Felt-tipped pen

Drill bit: 5/64-inch (2mm)

Pin vise

Diagonal cutters

Note

: This section covers the installation and

connection of the throttle linkage. If you have installed

an electric power system you can skip this section of

the manual.

Step 1

Locate the pushrod snap link. This will be used to secure the

pushrod wire to the throttle servo horn.

Step 2

With the radio system on, move the throttle stick and trim on

the transmitter to the center. Remove the throttle servo horn

from the servo. Rotate the horn so the arm that aligns with

the throttle pushrod measures 1/2-inch (13mm) from the

center of the horn, which aligns with the outer hole of the

servo horn.

Step 3

Move the throttle stick to the closed throttle position at the

transmitter. Pull the throttle linkage so the carburetor at the

engine is closed. Use a felt-tipped pen to mark the pushrod

wire where it crosses the hole on the servo horn that is 1/2-

inch (13mm) from the center of the horn.

Step 4

Use the radio to move the servo to the open throttle position.

Push the linkage to open the carburetor. The line made in the

previous step should align with the same hole on the servo

horn. If the line is further forward than the servo horn, you

will need to use a longer servo horn or connect the clevis at

the carburetor closer to the center of the carburetor. If the

line does not move far enough you will need to use a shorter

servo horn or connect the clevis at the carburetor to a hole

farther away from the center or the arm. Adjust as necessary

so the servo movement is correct for your engine.

Note

: If using a computer radio you can use the travel

volume to adjust for minor differences. It is best to set it as

close mechanically to result in linear travel of the throttle.