-21-

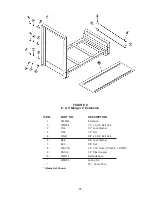

ITEM

PART NO.

DESCRIPTION

6’ HEAD

9’HEAD

1.

B17B

“

Jack Handle

2.

BFR4

“

Jack Pin & Chain

3.

BFR223

“

Jack

4.

SWM28

“

Light Bracket

5.

S414

“

Cap

6.

S415

“

Tube

7.

S418

“

Cap W/Hole

8.

S416

“

Hanger Bracket

9.

SWM5

SWM65

Pole

10.

F56

“

Lynch Pin

11.

SWM36

“

Washer-Pivot

12.

SWM14

“

Pivot Pin

13.

DWM39

“

Torque Arm

14.

DF1

“

Hydraulic Motor

*

WM225

“

Seal Kit

15.

DWM42

“

Right Motor Shield

16.

DWM27

“

Coupler

17.

DWM137

“

Cap Screw-Coupler

18.

DWM45

“

Motor Spacer

19.

R70

“

Cotter Pins 3/16’’ x 2’’

20.

BFR517

“

Cylinder Pin

21.

BFR69A

“

Cylinder

22.

DWM132

“

Pillow Block Bearing

23.

DWM36

“

Anti-Wrap Guard

24.

SWM30

“

Head Spacer

25.

SWM11

“

Driver Roller

26.

G23

“

Key 5/16’’ x 1-3/8’’

27.

DWM31

“

Shaft Shield

28.

SWM19

WM237

Conveyor Belt

29.

SWM37

“

Lacing Pin

*

SWM38

“

Cross Conveyor Lacing

30.

SWM7

SWM66

Main Frame

31.

SWM2

“

Caster

32.

BFR313

“

Roll Pin 5/16’’ x 2-3/4’’

33.

RG24

“

Bronze Washer 2’’ID x 3’’OD x 1/8’’

34.

BFR527

“

Bronze Bushing 2’’ID x 2-1/4’’OD x 2’’

35.

DWM59

“

Brake Bushing

ITEM

PART NO.

DESCRIPTION

6’ HEAD

9’HEAD

36.

WM286

“

Brake Band

37.

WM210

“

Spring-Red

38.

WM288

“

Brake Pad

39.

WM211

“

Brake Angle

40.

SWM3

“

Caster Mount

41.

K132

“

Spacer

42.

BFR57

“

Seal

43.

BFR58

“

Inner Bearing

44.

BFR59

“

Inner Race

45.

BFR60

“

Hub

*

BFR67

“

Wheel 5 x 15 (3)

*

BFR128

“

Tire 6.70 x 15SL (3)

46.

BFR143

“

Stud Bolt

47.

BFR144

“

Nut

48.

BFR61

“

Outer Race

49.

BFR62

“

Outer Bearing

50.

BFR63

“

Washer

51.

BFR64

“

Nut

52.

BFR65

“

Cotter Pin

53.

BFR66

“

Hub Cap

54.

SWM29

WM236

Skirt

55.

SWM34

“

Tightener Arm

56.

SWM33

“

Back Tightener Arm

57.

K68

“

Washer 1/2’’

58.

DWM125

“

Spring-Blue

59.

DWM25

“

Tightener

60.

R29

“

Nut 1/2’’

61.

SWM10

“

Conveyor Roller

62.

SWM16

WM235

Skirt Belt

63.

DWM51

“

Male Torque Arm

64.

HE42

“

Hose Holder (6)

65.

23N67

“

Hose Holder (4)

66.

WM287

“

I-Bolt

67.

SWM59

“

Skirt Extention

68.

5B10

“

Key 1/4” x 1” Woodruff

* (Means Not Shown)

“ (Means Same As Previous)

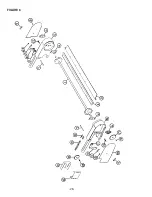

FIGURE 1

6’ & 9’ MERGER MAIN FRAME/POLE

Summary of Contents for M6

Page 4: ......

Page 15: ...15 LUBRICATION Continued B I Under Shield E G A C D F H A I Under Shield...

Page 19: ...DECAL LOCATION Continued A B L I K C Behind Shield Behind Shield A B 19 J D K I L C E G F...

Page 20: ...20 FIGURE 1...

Page 22: ...22 FIGURE 2...

Page 24: ...24 FIGURE 3...

Page 28: ...28 FIGURE 6...

Page 32: ...SERVICE NOTES 32...

Page 34: ...H S MFG CO products approved for the FEMA SEAL OF QUALITY...