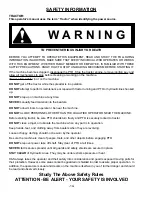

MAIN APRON ADJUSTMENT

Tighten the two adjusting bolts on both

sides (1 on each front corner of the

spreader - see circled area in the pictures

below) equally so that when properly

tensioned, the apron chain on each side

should sit 1/16” above the center driveshaft

support cross member.

The apron will be damaged if the machine

is operated with one end of the apron slats

running ahead of the opposite end.

ADJUSTMENTS

-23-

TIMING OF BEATERS

The vertical beaters on the manure spreader are preset

from the factory. If it becomes necessary to service

the beater assembly, the beaters must be timed so

the flighting of the opposite beater is about halfway

between the beater being timed.

To time the beaters;

1. Remove the top shield and bearing support from

both beaters.

2.

Lift/raise the beater up off of the gearbox splined

shaft.

3.

Rotate the beater so the flighting of the opposite

beater is about halfway between the beater being

timed.

4. Lower the beater on the splined shaft

5. Replace the bearing support and top shield.

Summary of Contents for 6180

Page 5: ...3 Remove Copy At Perforation...

Page 6: ...4 Intentionally Left Blank...

Page 8: ...Intentionally Left Blank 6...

Page 10: ...Intentionally Left Blank 8...

Page 13: ...11 SAFETY DECALS...

Page 14: ...12 SAFETY DECALS...

Page 15: ...13 SAFETY DECALS...

Page 17: ...15...

Page 31: ...DECAL LOCATION 9194A 11599 82602 82602 29 1494L 9194A 12794 093366 093020...

Page 35: ...DECAL LOCATION 33 51010 1906F DCAMB 093020 DCAMB 9194A 94012 94009...

Page 39: ......