110

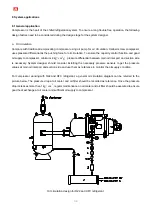

a. Economizer by sub-cooler

With this form of operation, a heat exchanger (refrigerant sub-cooler) is used to cool down liquid refrigerant. The

sub-cooling is achieved by injecting a small part of the refrigerant from the condenser into the sub-cooler. The

superheated vapor is pulled into the compressor at the Economizer connection and mixed with the vapor from the

evaporator, which has been already slightly compressed.

The sub-cooled liquid is at condensing pressure with this form of operation, the pipeline to the evaporator does

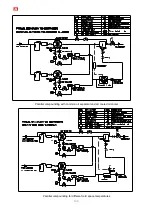

not therefore require any special features, aside from insulation. The system can be generally applied. Figure 6.24

shows the system with Economizer, sub-cooler.

ECO application by heat exchanger

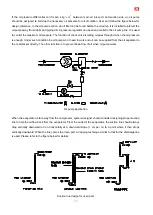

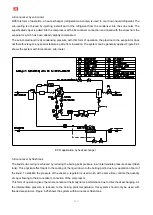

b. Economizer by flash tank

The liquid sub-cooling is achieved by reducing the boiling point pressure in an intermediate pressure vessel (flash

tank). This physical effect leads to the cooling of the liquid down to the boiling point, due to evaporation of part of

the liquid. To stabilize the pressure of the vessel, a regulator is used which at the same time controls the quantity

of vapor flowing to the Economizer connection of the compressor.

This form of operation gives the most economical thermodynamic performance due to direct heat exchanging. As

the intermediate pressure is reduced to the boiling point temperature, this system should only be used with

flooded evaporators. Figure 6.25 shows the system with Economizer, flash tank.

Summary of Contents for RC2-F Series

Page 6: ...5 2 2 Compressor outline...

Page 7: ...6...

Page 8: ...7...

Page 9: ...8...

Page 10: ...9...

Page 11: ...10...

Page 12: ...11...

Page 13: ...12...

Page 14: ...13...

Page 15: ...14...

Page 16: ...15...

Page 17: ...16...

Page 18: ...17...

Page 19: ...18...

Page 20: ...19...

Page 21: ...20...

Page 22: ...21...

Page 23: ...22...

Page 24: ...23...

Page 25: ...24...

Page 26: ...25...

Page 27: ...26...

Page 85: ...84 Horizontal External Oil Separator OS80 Horizontal External Oil Separator OS100 OS125 OS150...