LB

II

-PLUS Technical Manual

10

2.2.2

Specified lubricants for LB

II

-PLUS

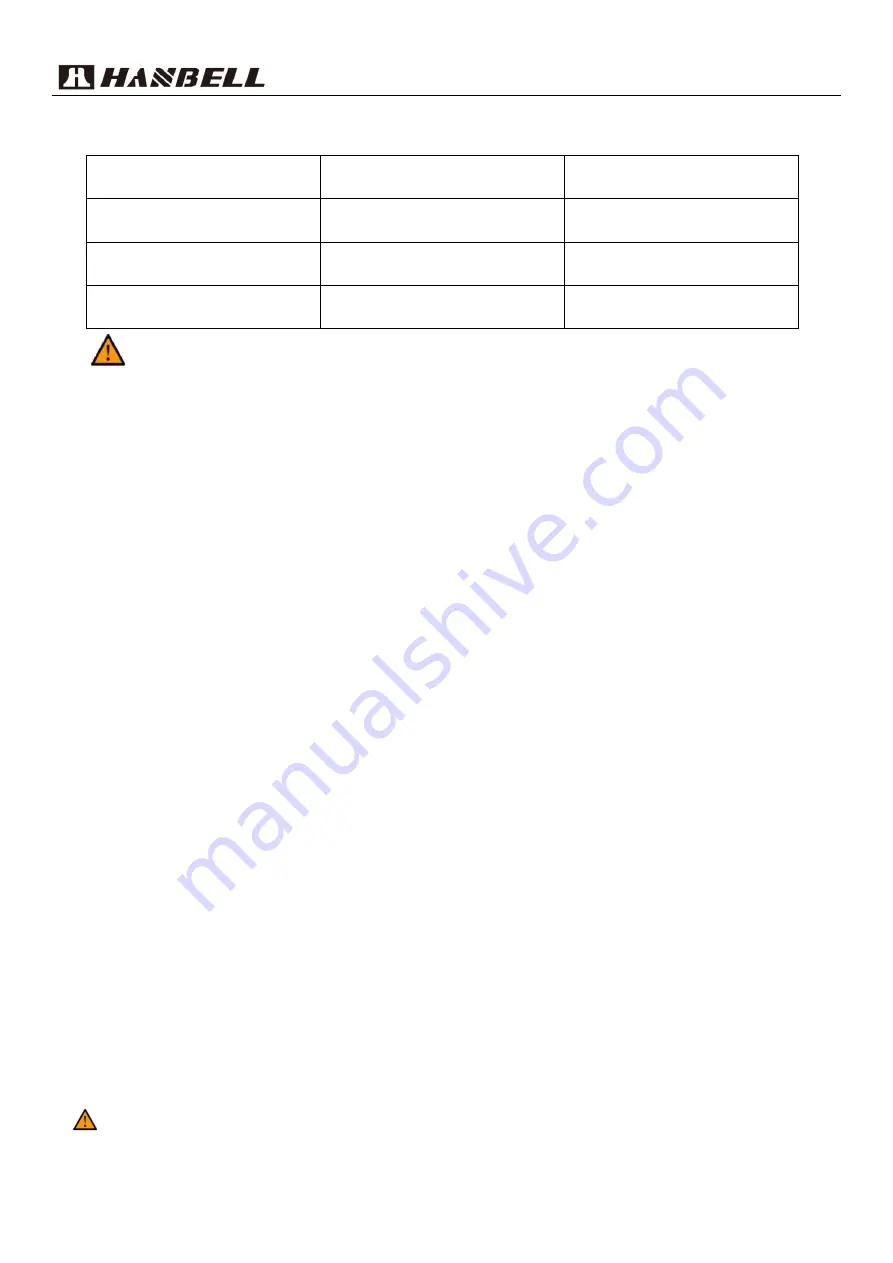

Table-2 Lubricant specification

Refrigerant

R22

R404A/R507

Type

HBR-B03

HBR-B05

Proportion

1.01

0.957

Specific heat40

℃

(

Kcal/kg K

)

0.43

0.43

Note

HANBELL only acknowledge the specified lubricant as written in above table.

Minimum starting temperature of the lubricant: 20

℃

.

When the compressor stops, please open the oil heater (exclude long term stop).

Lubricating oil for other refrigerants can only be used after confirmation with Hanbell.

2.2.3

Requirements for use and replacement of lubricating oil

Before filling the lubricating oil, the system should be kept clean. After the initial operation of 2000 hours, it is

recommended to refill the lubricant once more to ensure the long-term operation of the compressor.

Lubricating oil is easy to absorb the moisture in the air, so it should be avoided to be exposed to the air.

In order to keep as minimum as possible water contained in the system, it is suggested that the system

needs to be heated and evacuated as long as possible when the lubricant is replaced.

The foreign matter in lubricating oil will cause the blockage of the oil circuit. Therefore, the oil filter must

be installed to the external oil circuit, and the pressure difference switch must be installed before and

after the filter. When the pressure difference value reaches the set point (1.5bar), the oil filter must be

replaced or cleaned.

If the compressor runs under high temperature working condition for a long time, it will accelerate the

deterioration of the lubricating oil. Please check the chemical performance of the lubricating oil regularly

and shorten the interval of oil exchange.

The acidification of lubricating oil will affect the life-time of motor. when the lubricating oil PH≤6, it should

be replaced. (Please replace the system dry filter at the same time to ensure the system is dry).

If the compressor motor is burned, it will produce acid harmful matter and debris, and they will be

brought into the system together. The inspection should be carried out. Oil filters and lubricants must be

changed many times until the cleanliness and acidity of the oil line reach the standard. The lubricating oil

status needs to be traced regularly. Please replace it if the cleanliness and acidity beyond the standard

range. Please pay attention to the cleanliness and dryness of the system as well.

Warning: If the lubricating oil that isn’t authorized by Hanbell is used for compressor, HANBELL

will not be responsible for the coming problems.