7

OVLEREEQ*G OVLSREEQ*G OVLESREEQ*G OVLSEREEQ*G

97882C - (REV. A - 8/04)

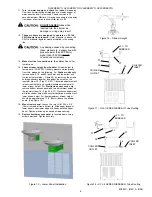

5.

Install the frame squarely in wall

opening with frame

upright edges flush with the finished wall surface. Place

shelf inside frame and line up the (2) holes on each. Insert

loose ends of rods into holes on sides of shelf panel. Using

appropriately sized screws or bolts (not provided), fasten

the shelf and frame to the bottom of wall opening.

Secure the frame sides and top to the wall opening using

(10) 5/16 bolts or screws (not provided).

NOTE:

Be sure that frame is squared in location. Do not

use less than the required screw quantity and

size.

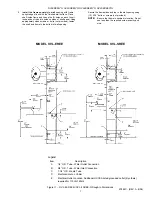

MODEL OVL-EREE

MODEL OVL-SREE

Legend

Item

Description

A

1/4 O.D. Tube - Water Outlet Connection

B

3/8 O.D. Tube - Water Inlet Connection

C

1-1/4 O.D. Waste Tube

D

Electrical Inlet on Chiller

E

Electrical Outlet Location. Additional UL/CSA listed grounded outlet (By others)

required for 115 Volt, 60Hz.

Figure 11 OVL-II EREE-Q/OVL-II SREE-Q Rough-In Dimensions