10

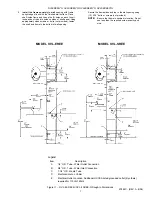

OVLEREEQ*G OVLSREEQ*G OVLESREEQ*G OVLSEREEQ*G

97882C - (REV. A - 8/04)

TROUBLESHOOTING & MAINTENANCE

Orifice Assembly:

Mineral deposits on orifice can cause water

flow to spurt or not regulate. Mineral deposits may be removed

from the orifice by poking with a small round file not over 1/8

diameter, or using a small diameter wire.

DO NOT

file or cut orifice material.

Stream Regulator:

If orifice is clean, regulate flow as in Step 14

of the installation instructions. If replacement is necessary, see

parts list for correct regulator part number.

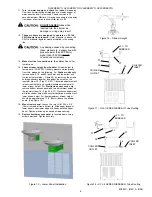

Actuation of Quick Connect Water Fittings:

Cooler is

provided with lead-free connectors which utilize an o-ring

water seal. To remove tubing from the fitting, relieve water

pressure, push in on the gray collar while pulling on the tubing

(See Figure 19). To insert tubing, push tube straight into fitting

until it reaches a positive stop (approximately 3/4).

Cleaning of Aztec Gold Models

requires special care.

Outer

surfaces must be cleaned with mild

detergent or a mixture of vinegar

and water only, rinsed and wiped

dry. Abrasive and acidic cleaners

may eventually damage the Aztec

Gold finish.

Figure 21 Regulator Mounting Mechanism

Figure 20 Push Arm Mechanism

28

14

24

15

Regulator

Mounting Bracket

43

Figure 22 Regulator Assembly

19

2

20

29

30

31

23

25

27

26

Stream Height

Adjustment

Sensor Control:

The sensor has a 2 second delay time. If

sensor fails to operate valve mechanism or operates

erratically, check the following:

a) Ensure there are no obstructions within a 40 inch radius from

the front of fountain.

b) Check wire connections at the solenoid valve and at the

sensor.

CAUTION:

Make sure unit is unplugged before

checking any wiring.

c) Ensure proper operation of solenoid valve. If there is an

audible clicking sound yet no water flows, look for a

obstruction in the valve itself or elsewhere in the water

supply line.

WARNING:

Do not expose sensor to direct

sunlight.

Sensor Range Adjustment:

The electronic sensor used in

this fountain is factory pre-set for a visual range of 36 inches. If

actual range varies greatly from this, or a different setting is

desired, follow the range adjustment procedure below:

a) Remove bottom cover of fountain.

b) Remove sensor by removing washers and nuts that secure

sensor on studs.

c) Locate range adjustment screw between the red lenses of

the sensor, then with a small tip screwdriver, rotate the range

adjusting screw clockwise to increase range or counter-

clockwise to decrease range. 1/4 turn of screw is equal to

approximately 12 - 18 inches of range.

CAUTION:

Complete

range of sensor (24 - 46 inches) is only one turn of the

adjusting screw.

d) Remount sensor on studs and replace bottom cover.

Figure 19 Quick Connect Fittings

29

26