Intrinsically safe

PP1095/2021/Issue 6

Page 6 of 8

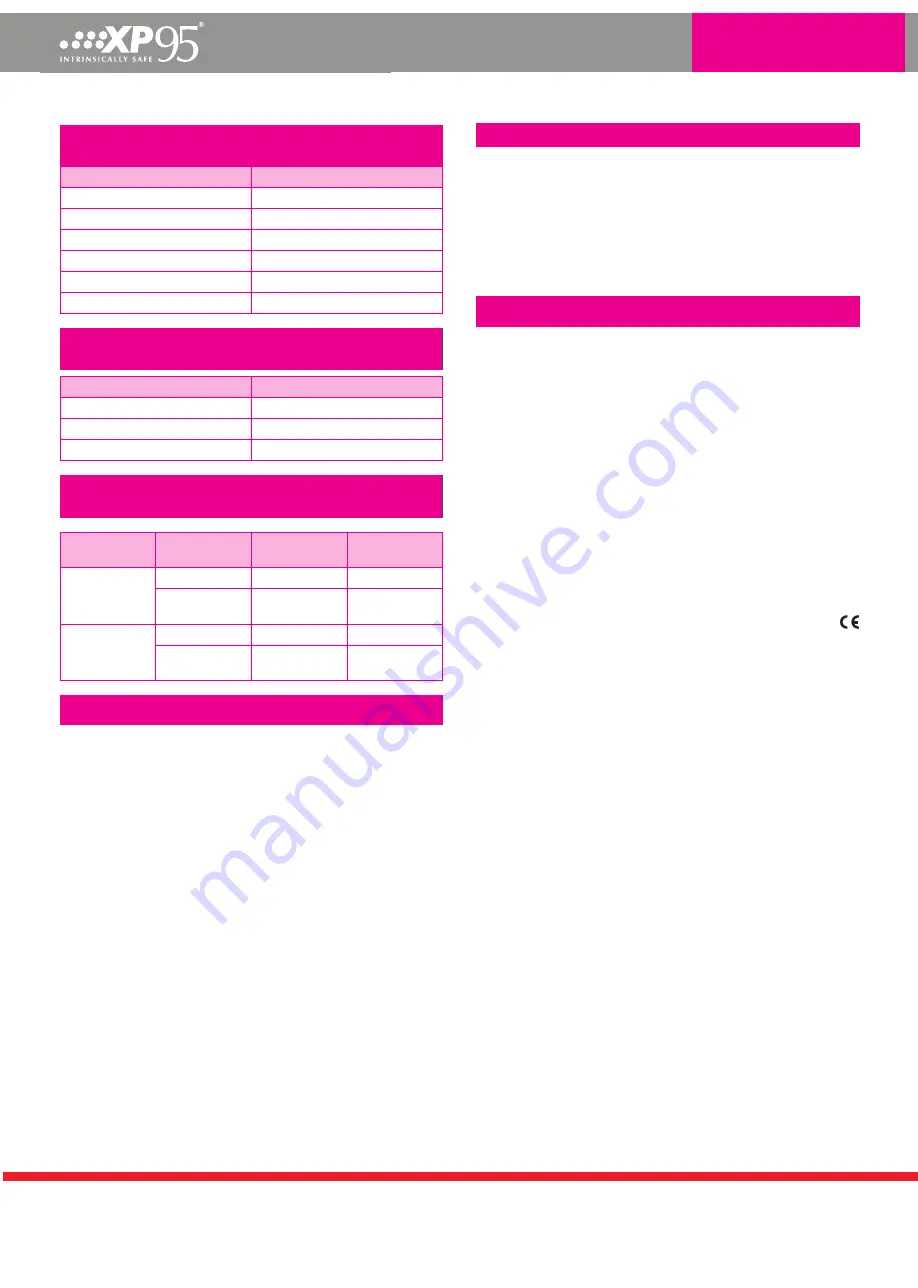

Table 5: Maximum loading 28 V/300 Ω single channel

barrier

Max. No of LEDs illuminated

Max. (Total) device load (mA)

0

8.0

1

7.0

2

6.0

3

5.0

4

4.0

5

3.0

Table 6: Maximum loading 28 V Galvanic Isolator Single

Channel Barrier

Max. No of LEDs illuminated

Max. (Total) device load (mA)

0

4.0

1

3.0

2

2.0

Table 7: Loading of the fire loop from a Translator and

Barrier pair

Characteristic

Zener Barrier

Galvanic

Barrier

Min Loading

Current (mA)

1

5

Capacitance

(nF)

1

90

Max Loading

Current (mA)

10

10

Capacitance

(nF)

80

170

Using Galvanically Isolated Barriers

Whilst the cable parameters in Table 4 specify the allowable limits

for energy storage in the Hazardous area wiring these values do

not generally allow reliable XP95 protocol transmission. This is

particularly true when using Galvanically Isolated Barriers. Due

to their design, these barriers present a relatively high capacitive

load on the main fire loop. Therefore, the main fire loop capacitive

loading and the I.S. spur capacitive loading must be carefully

considered when designing a fire system.

The maximum impedance allowed on the I.S. spur is 15 ohms and

80nF, which is typical of 500m of FP200 cable.

The maximum capacitive load that can be tolerated on the fire loop

will be defined by the Control Panel manufacturer. The capacitive

load of the IS zone includes 90nF for the galvanic barrier and the

total cable capacitance (80nF maximum). This should be added to

the main fire loop capacitance and compared with the fire panel

specification.

Additionally, a galvanic barrier will add 5mA to the system load

which should be added to the loop loading calculations.

The loop calculations for each I.S spur often use the maximum

load of 10mA and 200nF as the equivalent load on the fire main

loop. Any calculation must ensure that the translator has at least

19V at the translator input.

Servicing

Servicing of I.S. fire detectors may be carried out only by a

BASEEFA authorised body. In practical terms this means that

Apollo XP95 I.S. fire detectors may be serviced only by Apollo at its

factory. Servicing of the fire protection system should be carried

out as recommended by the code of practice BS 5839-1 or other

local regulations in force. For more information on servicing Apollo

detectors, please refer to the care, service and maintenance guide,

PP2055.

Approvals

XP95 I.S. detectors have been approved by LPCB to EN54 and the

XP95 I.S. Manual Call Point, Part No 55100-940, is LPCB approved

to EN54-11. These products have also been approved for marine

use by the following bodies:

• American Bureau of Shipping

• Bureau Veritas

• DNV GL

• Lloyds Register of Shipping

• China Classification Society

• Korean Register of Shipping

Details of approvals held are available on request.

The product certification technical files for the XP95 I.S. range are

held by BASEEFA in accordance with the requirements of the ATEX

Directive 2014/34/EU. All detectors and manual call points are

marked.