Intrinsically safe

PP1095/2021/Issue 6

Page 2 of 8

The voltage limitation arises because of the need for safety

barriers. The barriers used with Apollo I.S. detectors are rated

at 28 volts, the highest rating that is commercially available.

These are used to limit the voltage inside the hazardous area to a

(practical) maximum of about 26 V dc. Although this is within the

standard XP95 protocol specification, it is lower than that provided

by most loop drivers.

The safety barrier is also responsible for the current limitation

because the 28 V barriers have a series resistance of at least

300 ohms. This resistance results in unacceptable voltage drops

if the normal 20 mA current pulses are used. It has therefore

been necessary to reduce the amplitude of the current

pulses to 10 mA.

XP95 Protocol Translator

In order to enable the use of standard control and indicating

equipment in intrinsically safe systems, Apollo has developed

a device to ‘translate’ voltage levels from any loop driver

operating within the XP95 limits to levels compatible with the

I.S. requirements. The translator also ‘boosts’ the current pulses

returned by the I.S. detectors from 10 mA to 20 mA, thereby

ensuring compatibility with standard loop driver thresholds. For

more information regarding the XP95 Protocol Translator refer to

PP5034.

System design

The design of an intrinsically safe fire detection system should

only be undertaken by engineers familiar with codes of practice

for detection systems and hazardous area electrical systems.

In the UK the relevant standards are BS5839-1 and BS EN 60079-

14 respectively.

The fire detection performance of the XP95 I.S. range is the same

as that of its standard counterparts. Performance information is

given in the XP95 I.S. products data sheets.

The BASEEFA certification of the I.S. devices covers their

characteristics as components of an intrinsically safe system and

indicates that they can be used with a margin of safety in such

systems. The precise way in which the system can be connected

and configured is covered by an additional, ‘system’ certification.

The System Diagram, Z20982, see Figure 6, details cable

parameters and permissible configurations of detectors, manual

call points and safety barriers which are certified by BASEEFA. Any

user wishing to install a system outside the parameters given on

this system diagram cannot make use of the Apollo certification

and should seek independent certification from a competent

certification body.

The BASEEFA system Certificate Number is BAS21Y0069 / IECEx

BAS21.0014

Any system installed within the parameters specified in Z20982

should be marked in accordance with BS EN 60079-25. The

marking should include at least ‘Apollo XP95 I.S. Fire Detection

System, BASEEFA No BAS21Y0069 / IECEx BAS21.0014

In safe area (standard) applications it will be normal practice to

connect the wiring as a loop, with both ends terminated at the

control panel. In the event of an open-circuit fault it is then possible

to drive both ends simultaneously. In a hazardous area it is not

possible to use a loop configuration because the potential to feed

power from each end of the loop would double the available energy

in the hazardous area and contravene the energy limitations of the

I.S. certification. All XP95 I.S. circuits must therefore be connected

as spurs from the safe area loop or as radial connections from the

control panel.

It is recommended, for the highest system integrity, that each I.S.

circuit be restricted to a single zone and that the connection from

the safe area loop to the I.S. spur be protected on each side by XP95

isolators. The DIN-Rail dual isolator (55000-802) is particularly

suited to this application. This configuration, shown in Figure 1 will

conform fully with the requirements of BS5839-1 and with local

codes since a single wiring fault will result in the loss of only one

zone of detection.

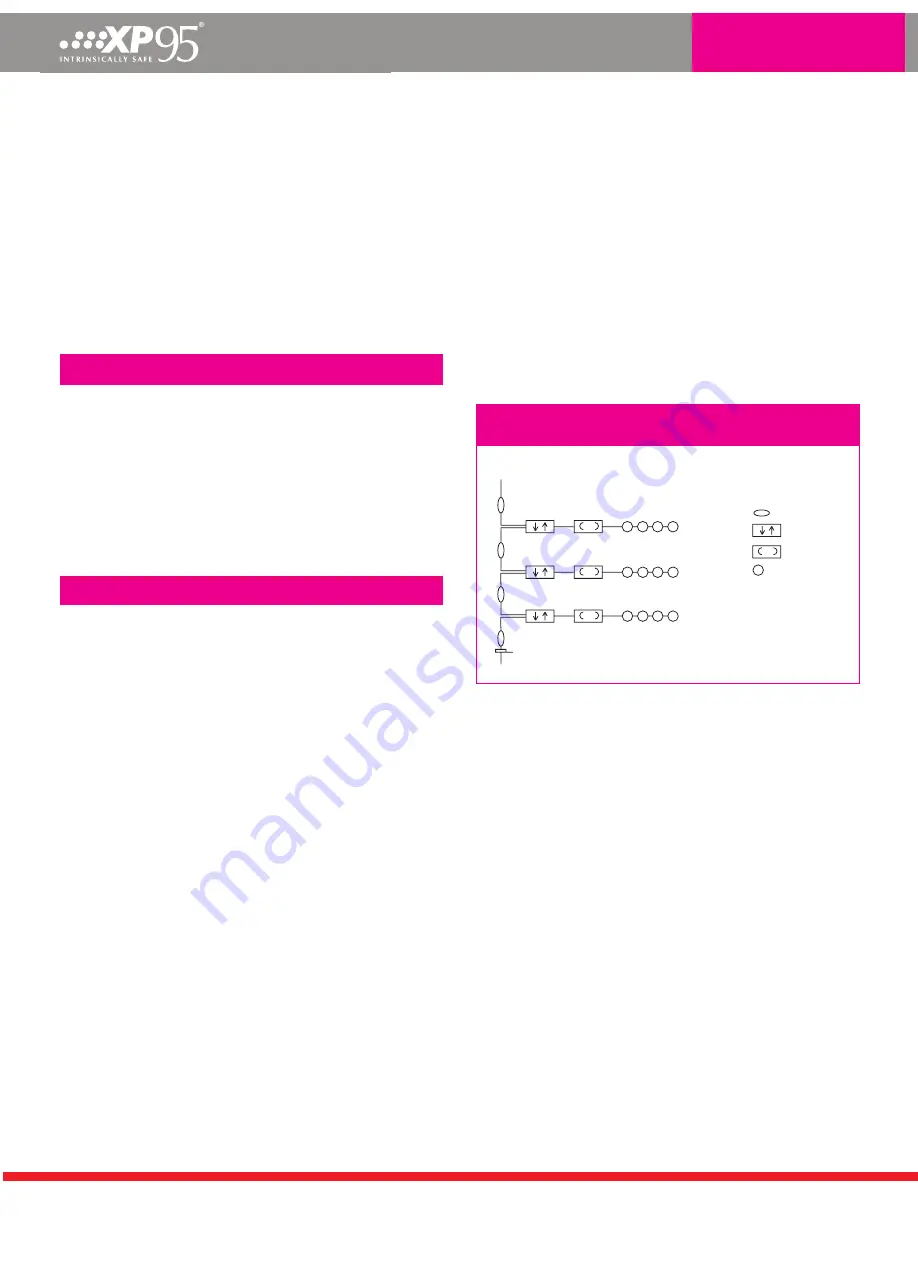

Figure 1: Schematic wiring diagram of XP95 I.S. circuit

to BS5839

XP95 Loop

in Safe Area

2 core

IS Zone n+2

IS Zone n+1

IS Zone n

Key

XP95 IS Isolator

XP95 IS Protocol Translator

Safety barrier

XP95 IS Detector

In certain circumstances it may be possible for the simpler

configuration, shown in Figure 2 to be used. This arrangement

may include single or dual-channel translators, housed, together

with the critical wiring, in a robust mechanical housing such as

the Apollo DIN-Rail enclosures part no. 29600-239 (1 x I.S. circuit)

or part no. 29600-240 (up to 5 x I.S. circuits). For further advice,

please contact the Technical Support Team at Apollo.