Reassembly

1.

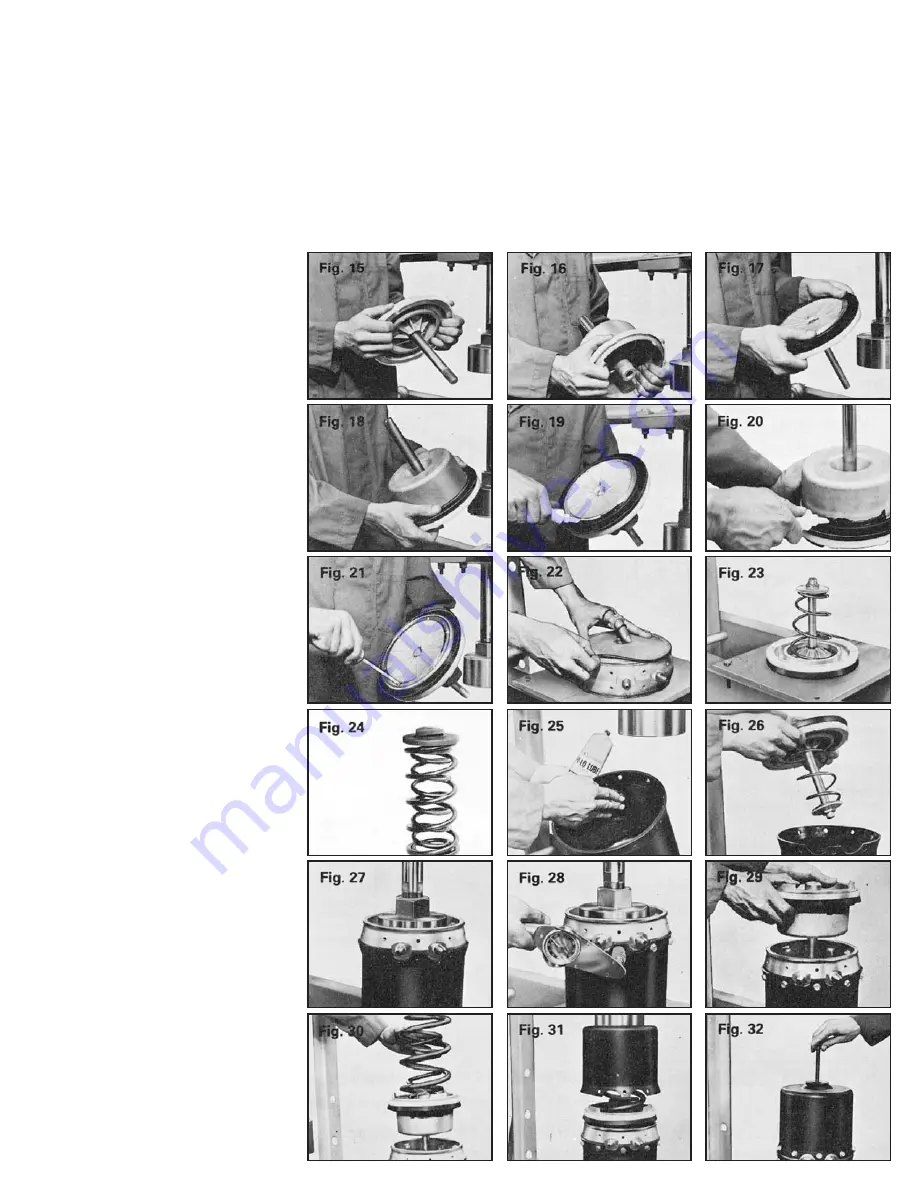

Install service piston bearing such

that concave portion of the bearing

provides support for packing cup and all

tabs are snapped over piston flange

(Fig. 15). Properly seat packing cup

(Fig. 17).

2.

(Packing Cup Emergency Piston)

Install piston bearing and packing cup as

described in Step 1 (Fig. 16 & 18).

(O-Ring Emergency Piston)

Assemble piston bearing with tab seated

in O-ring groove and positioned over

piston flange facing open end. Pack

O-ring groove and completely cover

O-ring with supplied lubricant. Install

O-ring, (skip 3, 4, 5 below).

3.

Sealing surfaces on packing cups

and piston must be free of all dust,

grease and oil. Apply sealing compound

to service piston (Fig. 19) and, if

applicable, emergency piston (Fig. 20).

Smooth beads between inner lip of

packing ring and piston. MAKE SURE

NO COMPOUND IS ON OUTER LIP.

Install retainer ring and self-tapping

screws.

4.

The sealing surfaces must be free of

all dust, grease and oil. Apply the sealing

compound to the service piston (Fig. 19)

and emergency piston (Fig. 20). Smooth

the beads of sealing compound. The

compound seals the inner lip of the

packing cup to the piston. Make sure

there is no compound on the outer lip.

5.

Install retainer ring and self-tapping

screws on service piston (Fig. 21) and

allow the compound beneath the retainer

ring to set for at least eight hours before

assembling the piston into the cylinder.

6.

Lubricate the large seal grooves of

the center boss with supplied lubricant

and install the small O-ring, nylon

bushing and snap ring in the middle of

the unit. Be sure the flat flange surface

of the bushing contacts the O-ring.

Install the two larger O-rings in the outer

seal grooves of the bulkhead (Fig. 22).

7.

Compress the return spring on the

service piston. Make sure the large

diameter of the spring is toward the

piston. Install the return spring locator

and jam nut (Fig. 23).

8.

Insert the booster spring into the

heavy spring and align the coil ends so

they are 180º opposite. Place the spring

locator on the springs and the new filter

over the hole in the locator (Fig. 24).

9.

Lubricate the bores of the service

and emergency cylinders with supplied

lubricant (Fig. 25).

10.

Place the service cylinder in the

press and install the service piston

assembly (Fig. 26). Make sure the jam

nut centers on the push rod hole of the

cylinder.

11.

Place the bulkhead with the

concave side up, into the service

cylinder. Press together (Fig. 27),

aligning the cap screw holes, and install

the cap screws (Fig. 28) at 100 in.-lbs.

(8.3 ft.-lbs) to 125 in.-lbs. (10.9 ft.-lbs.)

torque. NOTE: Over tightening can

cause the cap screw threads to strip.

12.

Place the emergency piston with

the piston rod into the center boss

(Fig. 29).

13.

Place the springs, locator and

filter into the emergency piston (Fig. 30).

14.

Place the emergency cylinder over

the springs. Make sure the spring

locator and filter are centered in the

cylinder.

15.

Press the emergency cylinder

down to the bulkhead (Fig. 31). Align

the cap screw holes and install the cap

screws securely with the same torque as

used in Step 11.

16.

Apply air pressure to the

emergency inlet and install the release

bolt and washer (Fig. 32).

17.

Remount the unit on the vehicle.

Be sure the service filter is replaced with

the new one furnished in the

service kit. Also, make sure the rubber

plug is pressed into the release bolt hole

after the bolt is removed. This plug

prevents contaminants from entering

through an unfiltered passage.

18.

Adjust brakes per vehicle

specifications so the stroke of the

actuator is as short as possible and the

shoes do not drag. The brake adjuster

should be approximately 90º to the push

rod when brakes are fully applied and

adjusted.

19.

Test the brake operation before

removing wheel blocks.