4

MOTOR CONTROLS

SAFE USE

Ensure that this Manual has been read and

understood by the operator.

This appliance is not intended for use by

young children or infirm persons without

supervision. Young children should be

supervised to ensure that they do not play

with the appliance.

Only trained operators should use this

appliance and be familiar with its

adjustment and use.

When the motor has switched off from overheating,

allow sufficient time for it to cool, then press switch

to reset.

START UP

Unwind the electrical cord and plug into power

point.

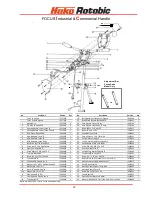

Adjust handle to comfortable waist height refer to

Pic 18.

Rotate wheels OFF the floor refer to Pic 18.

Check that the power indicator lamp is ON.

Push the Safety Interlock Lever forward to dis-

engage safety lock refer to Pic 15.

Squeeze the start/run lever one side only, which

will START the machine refer to Pic 16.

DISPENSING

(FOCUS SUDS models)

Press Switch as shown in Pic 17. Dispensing only

occurs while switch is being pressed.

Manual Reset Thermal

Over Load Switch.

Pic 14 Motor Thermal Overload Switch

Pic 15 Dis-engaging the Safety Interlock.

Pic 16 Squeeze Start/Run Lever for Operating.

Squeeze

lever

Squeeze

Lever

Squeeze Lever

Pic 17 Activation of Solution Dispensing

Push Forward

FForward

Press and

Hold to

Dispense