Tip Maintenance

1. Set the temperature to 250℃ (482℉).

2. When the temperature stabilizes, clean the tip with the cleaning sponge and check the condition of the tip.

3. If the solder plated part of the tip is covered with black oxide, apply fresh solder containing flux, and clean

the tip again. Repeat until all the oxide is removed, then coat the tip with fresh solder.

4. If the tip is deformed or heavily eroded, replace it with a new one.

CAUTION

Do not file the tip in an attempt to remove the black oxide.

WARNING

Since the soldering iron can reach a very high temperature, please work carefully.

Except the case especially indicated, always turn the power switch OFF and disconnect the

power plug before performing any maintenance procedure.

●

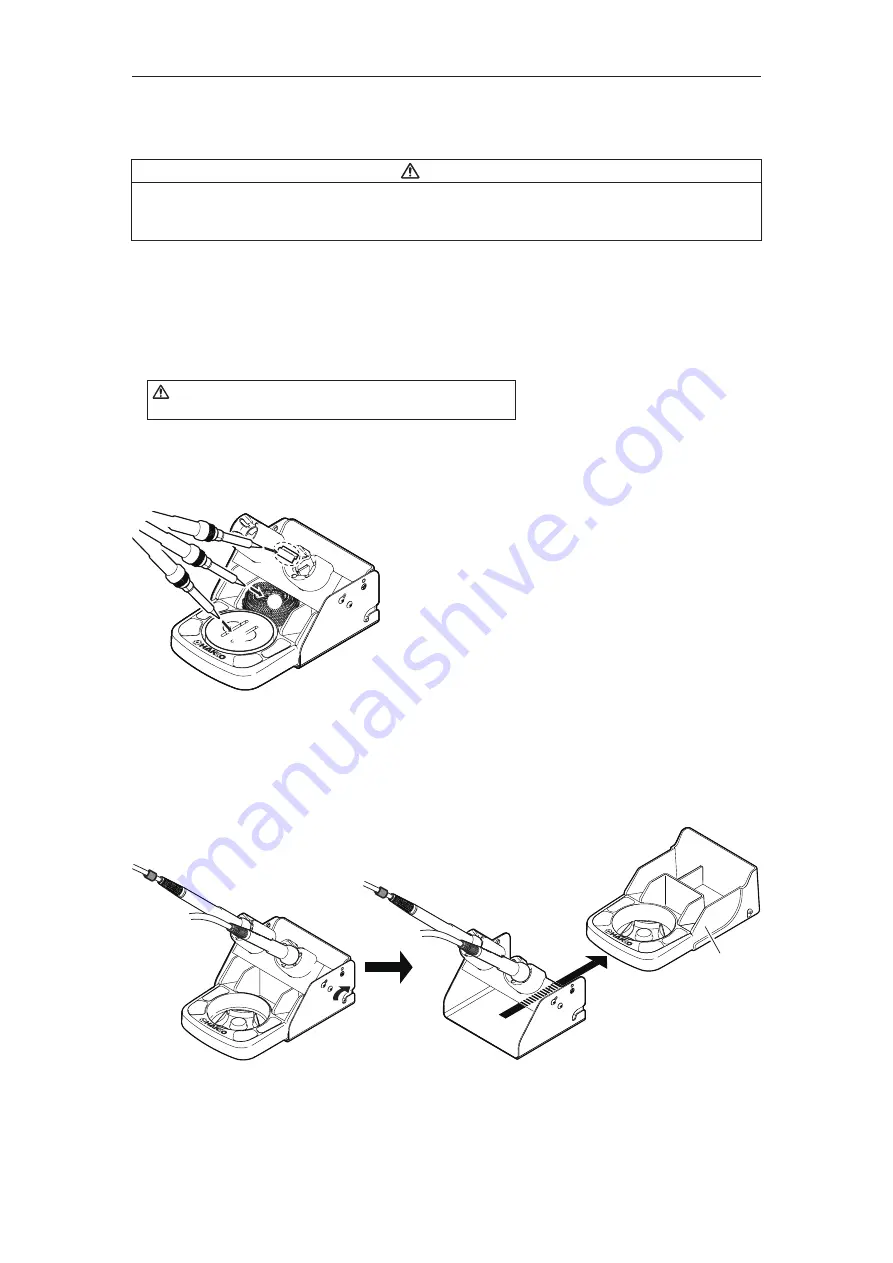

Cleaning the tip using the iron holder

A

B

C

Holder base

Remove

7. MAINTENANCE

Performing proper and periodic maintenance extends product life. Efficient soldering depends upon the

temperature, quality and quantity of the solder and flux.

Apply the following service procedure as dictated by the conditions of usage.

HAKKO FH-801 iron holder has a removable holder base. When solder debris

accumulates, remove the holder base, and properly dispose of the contents.

●

Cleaning of solder fragments

A. Using the cleaning sponge

Use the cleaning sponge that comes with the product to

clean the tip. It offers wide-ranging uses, from simple

removal of excess solder to complete elimination of matter

occurring as a result of oxidization.

B. Using the cleaning wire

Material that is not removed easily with the cleaning

sponge can likely be removed using the cleaning wire.

C. Using the rubber plate

Wipe the iron lightly across the rubber ring to remove

excess solder from the tip.