34 / 47

Hakki Pilke 50 Pro

Translation

Version 1-2018

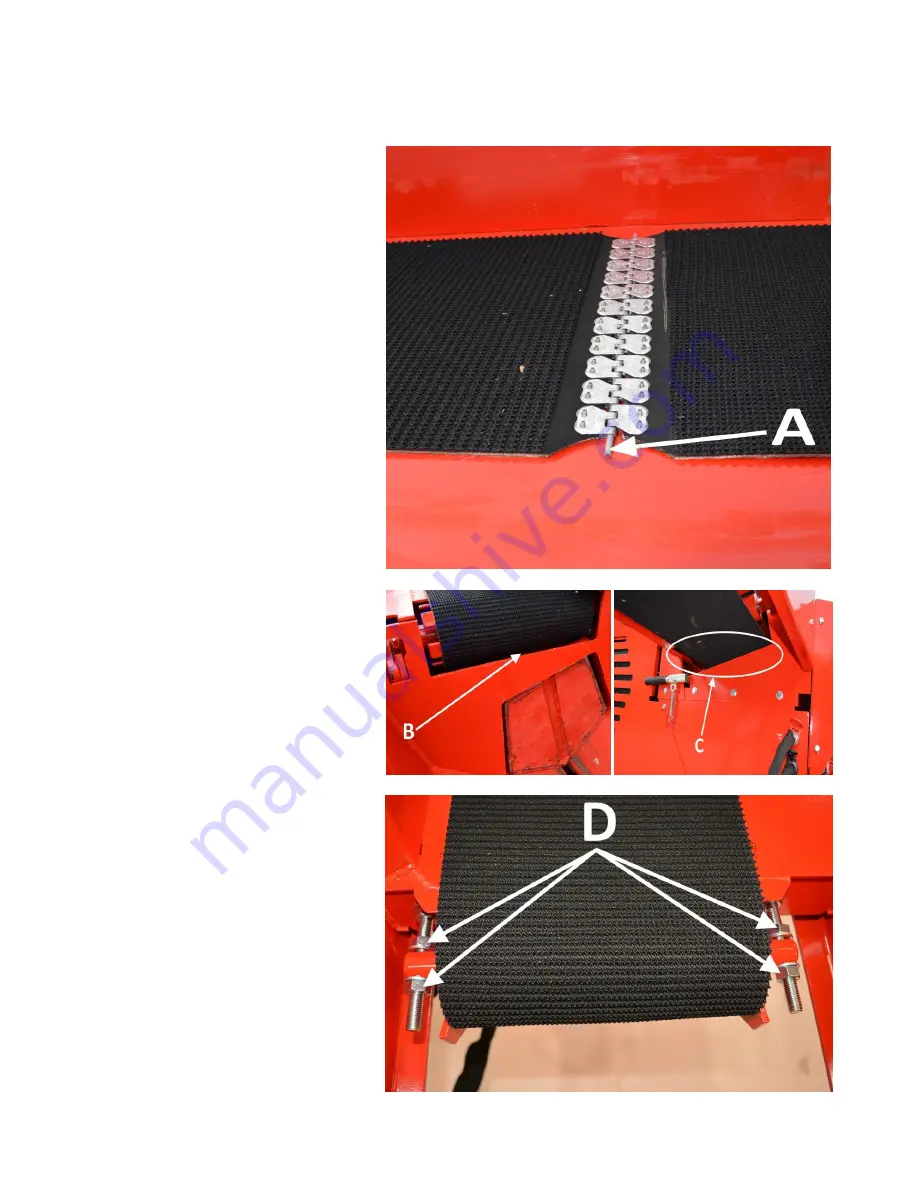

5.4.

Conveyor maintenance

5.4.1.

Replacing and tensioning the in-feed conveyor belt

Replace the in-feed conveyor belt as

follows:

1.

Shut the machine down and

disconnect it from its power

sources.

2.

Raise and lock the in-feed

conveyor into the transport

position. (See Section 3.1.1.)

3.

Move the belt joint to a

suitable height.

4.

Disconnect the joint by using,

for example, pliers to pull out

pin A (Figure 31) holding the

joint together.

5.

Remove the old belt.

6.

Slide the new belt under the

table through opening B at

the side of the in-feed

conveyor's drive roller until

you can pull the belt out from

the other end C.

7.

Lead the rest of the belt

under the log press, around

the rear roller and, finally,

behind the conveyor.

8.

Connect the joint by inserting

pin A into the joint.

9.

Turn the conveyor back to the

operating

position

and

tension the belt.

10.

Finally, adjust the belt to the

correct tension and to run

straight with the help of the

adjustment nuts D.

The belt is at the correct

tension when its middle

section is raised approx. 5 cm

when the conveyor is in the

operating

position.

An

excessively tight belt may be

damaged more easily, and it

places unnecessary strain on

the bearings of the conveyor.

Figure 31.

Figure 32. Figure 33.

Figure 34.