-14-

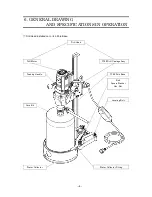

5) After completion of 1) - 4), pull out Clutch Adjusting

Pin. Hang Single-ended Wrench 36mm on the

Main

Shaft and then stick the main shaft by a handle of the

wrench touching the pole. Make sure that the main

shaft is locked. Turn the motor switch on for just a

moment and make sure that the clutch is slipping

without motor locking.

WARNING

Be careful for the position of Single-ended Wrench 36mm touching on pole.

(See the drawing)

6) After making sure the clutch is slipping, install Hex. Plug 1/8” back into the hole.

4.Checking of attaching screws

◎

Check every attaching screws for loosening periodically. If found loose, tighten it.

Summary of Contents for SPZ-252U2i

Page 19: ...17 MEMO...