HAIER CHILLER

stop

3.Lack of refrigerant

2.Re-adjust the set temperature

3.Recharge the refrigerant

Discharging pressure

is too high

1.Pipe or filter is blocked

2.Refrigerant is too much or there is

non-condensed gas

3.Condenser is dirty and heat

releases badly

1.Clean pipeline, change the filter

drier

2.Release the redundant refrigerant

or the non-condensed gas.

3.Clean the condenser

Discharging pressure

is too low

1.Lack of refrigerant

2.Compressor failure

1.Recharge refrigerant

2.Change the compressor

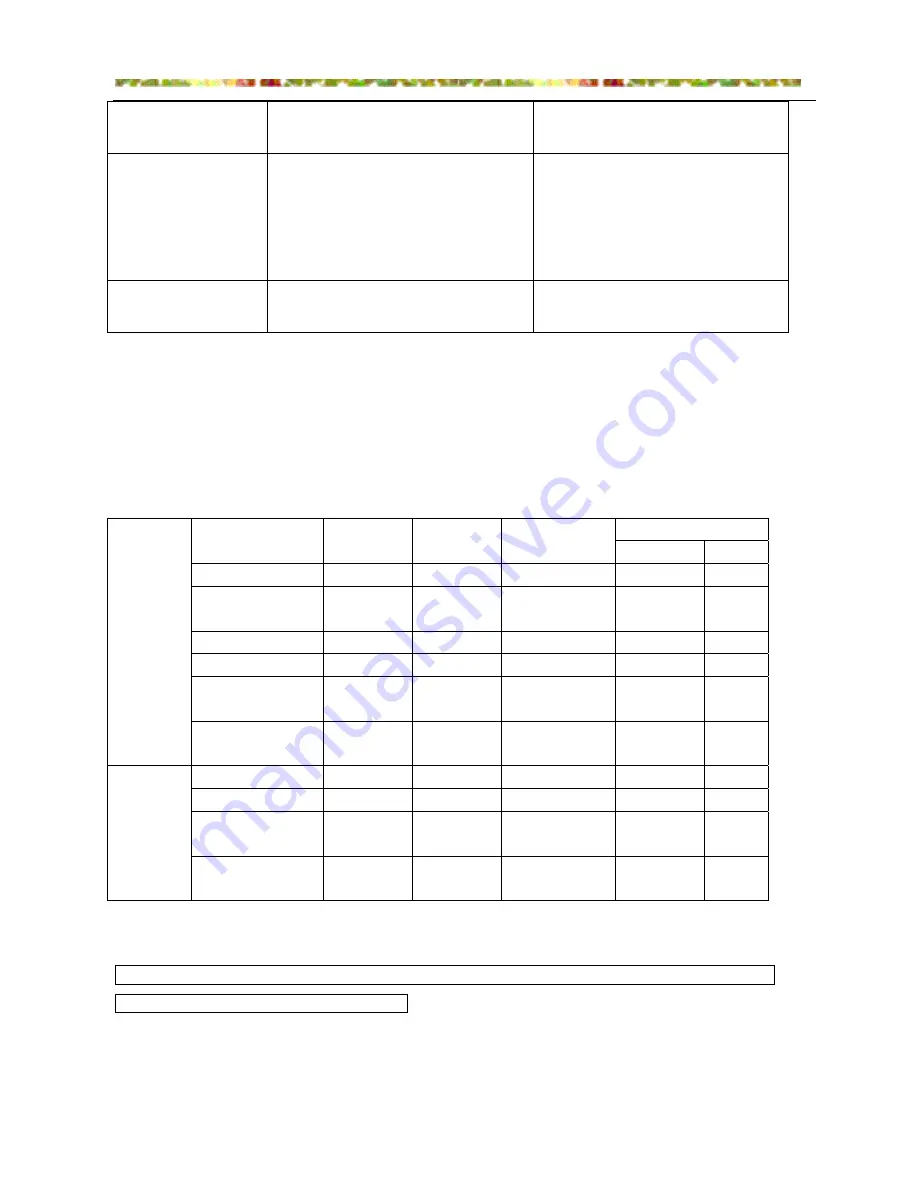

19. Water quality management

If the quality of chilled water and cooling water is bad, it not only will cause dirty in the heat transmission

pipe, effect the heat exchanging efficiency, lower the unit performance, but also make corrosion in the pipe,

which will result in the serious problem. The customer should deal with the water according to the below

table. In the chilled water system, the soft water should be utilized. Check the water quality in a certain

period; if it cannot pass the requirement, measures should be taken immediately.

20. Daily maintenance

Note: Before performing any maintenance and repair to the unit, please cut off power supply.

Electricity leakage will cause body injury.

In order to exert the unit's performance fully, must pay attention to the following items:

1. Electric wire Connection:

the power supply provided should be within the compressor permitted

range.

Tendency

Item Unit

Recharge

water

Chilled

(cooling) water

Corrosion Dirty

PH value (25

℃

)

6.5-8.0

6.5-8.0

0

0

conductance

(

25

℃

)

μ

S/cm

<200 <800

0

0

Chlorine ion (Cl

-

) mg

Cl

-

/L <50

<200

0

Vitriol ion (SO

-2

) mg

SO

-2

/L <50

<200

0

Acid consumption

(

PH4.8

)

mg

CaCO

3

/L

<50 <100

0

Basic

items

Full rigidity

mg

CaCO

3

/L

<50 <200

0

Iron

(

Fe

)

mg Fe/L

〈

0.3

<1.0 0 0

Sulfur ion

(

S

2-

)

mg S

2-

/L /

/

0

Ammonium ion

(

NH

4

+

)

mg NH

4

+

/L

〈

0.2

<1.0 0

Reference

items

Silicon dioxide

(

SiO

2

)

mg SiO

2

/L <30

<50

0