12

8. PURITY / CONVERGENCE ADJUSTMENT

PURITY ADJUSTMENT

1.

Demagnetize CRT with the demagnetizer.

2.

Loosen the retainer screw of the deflection yoke.

3.

Remove the wedges.

4.

Input a green raster signal from the signal generator,

and turn the screen to green raster.

5.

Move the deflection yoke backward.

6.

Bring the long lug of the purity magnets on the short

lug and position them horizontally. (Fig2)

7.

Adjust the gap between two lugs so that the GREEN

RASTER will come into the centre of the screen.

(Fig. 3)

8.

Move the deflection yoke forward, and fix the position

of the deflection yoke so that the whole screen will

become green.

9.

Insert the wedge to the top side of the deflection yoke

so that it will not move.

10. Input a crosshatch signal.

11. Verify that the screen is horizontal.

12.

Input red and blue raster signals, and make sure that

purity is properly adjusted.

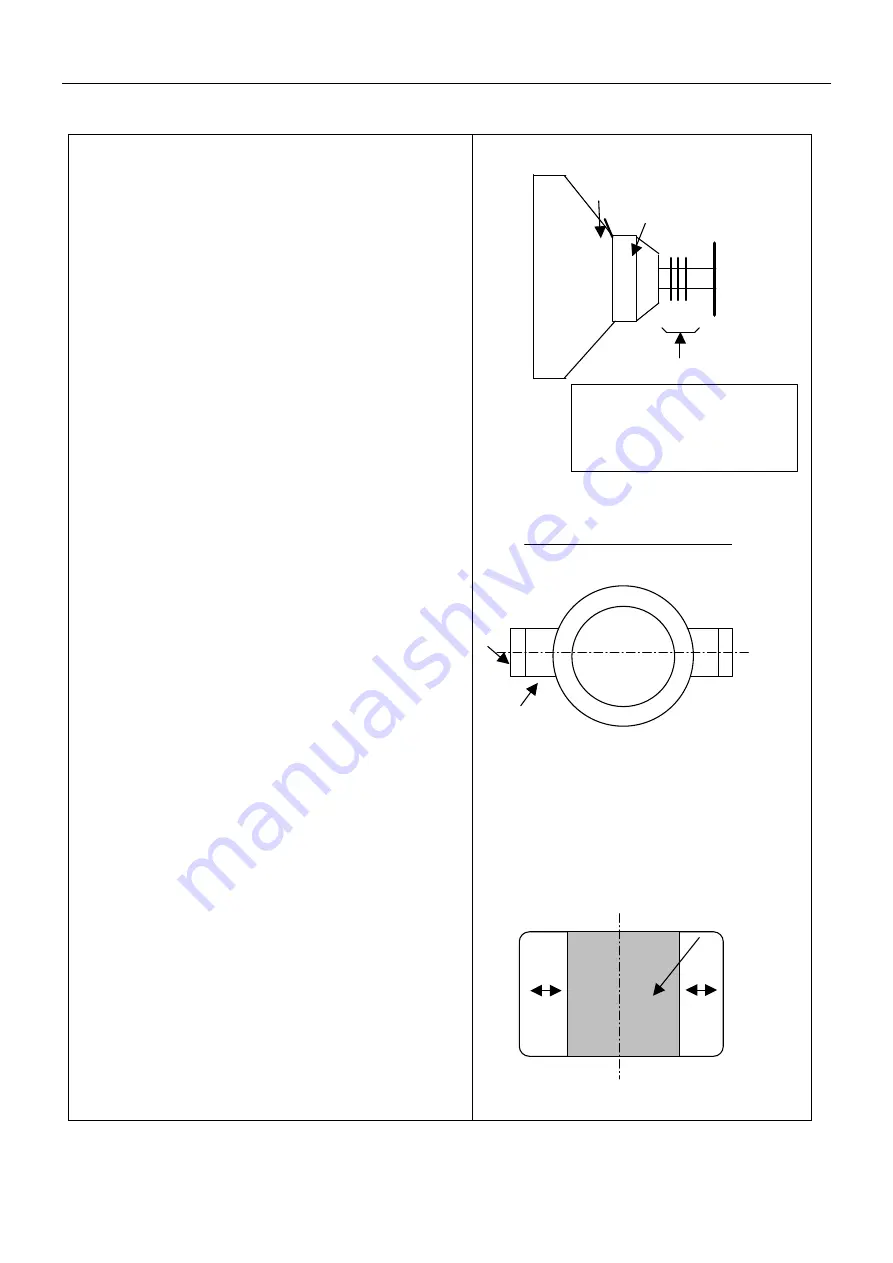

CRT

WEDGE

DEFLECTION YOKE

P

4 6

P: PURITY MAGNET

4: 4-POLES

(convergence magnets)

6: 6-POLES

(convergence magnets)

P/C MAGNETS

Fig. 1

PURITY MAGNETS

Long lug

Short lug

Bring the long lug over the short lug and

position them horizontally.

Fig. 2

(FRONT VIEW)

GREEN RASTER

CENTER

Fig. 3