Installation and Maintenance Manual, Compact CBP

Installation

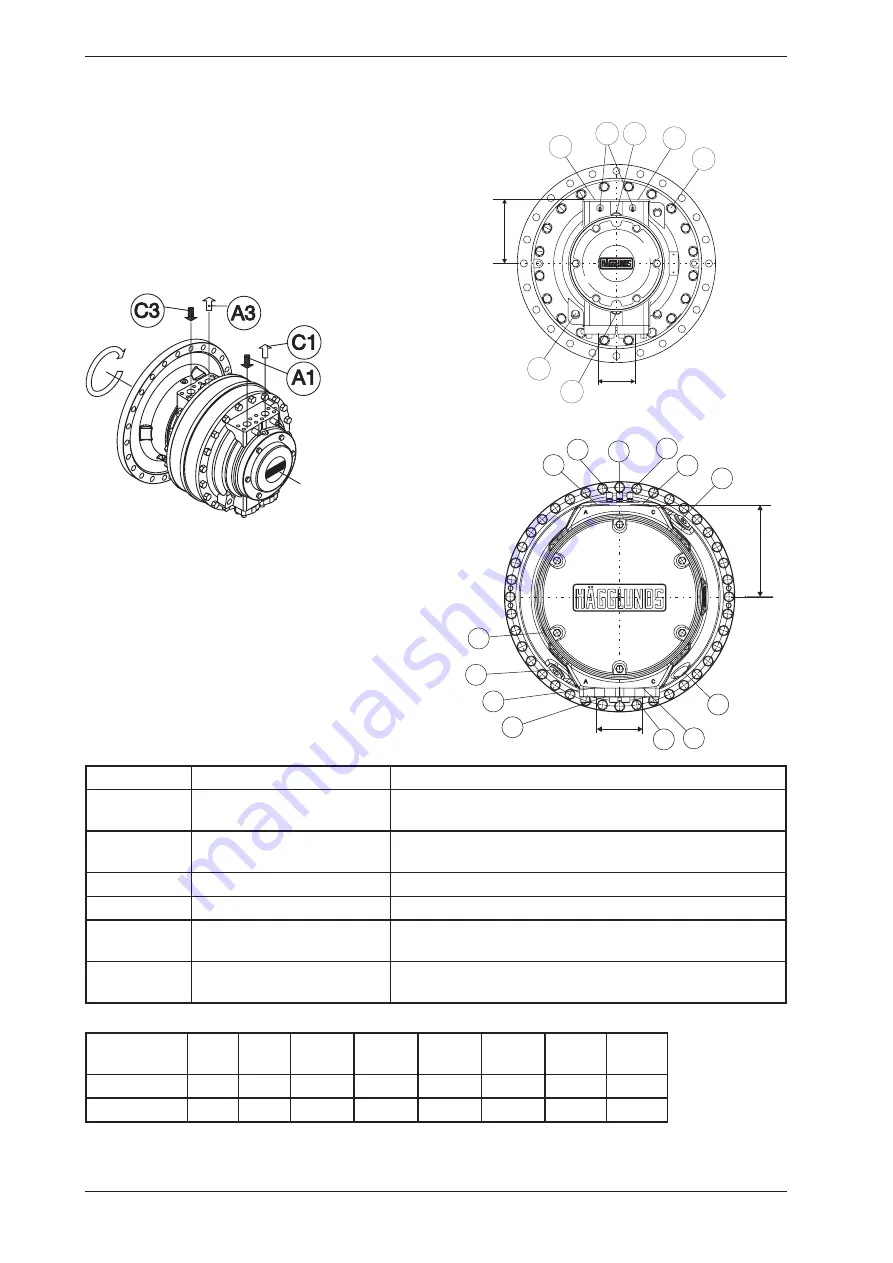

**SAE coupling J 518 C, code 6, 414 bar (6000 psi).

Fig. 3.25a CBP 140

When using (heavy wall) piping and in frequent

reversal drives, it is recommended to fit flexible

hoses between the motor and piping to avoid

damage due to vibration and to simplify

installation of the motor. The length of the

hoses should be kept fuirly short.

3.2 Oil connections

Fig. 3.25 CBP 140

Connection

Description

Remarks

C1, A

Main connection

If C1and A is used as the inlet, the motor shaft rotates

clockwise, viewed from the motor shaft side*.

A1, C

Main connection

If A1 and C is used as the inlet, the motor shaft rotates

counterclockwise, viewed from the motor shaft side*.

D1

Drain outlet

Normally plugged at delivery.

D, D, D4

Alternative drain outlets

Normally plugged at delivery.

F, F, F4,

F5, F6

Flushing connection

For flushing of motor case.

T

Test connections

Used to measure pressure and/or temperature at the

main connections.

Motor

A**

C**

D1, D2,

D3, D4

F3, F4,

F5, F6

y mm

y in

x mm

x in

CBP 140

1 1/4" 1 1/4"

G /4"

G 1/4"

188

7,40

99

,90

CBP 80-840

"

"

G 1 1/4

G 1/4"

10

1,0

17

5,9

A1

F3

T

C1

D1

D2

F4

y

X

Fig. 3.25b

CBP 280-840

y

X

A1

F2

D2

T4

A2

C2 T4

T3

T1

T2

T1

C1

D1