4500 Series Surface Vertical Rod Exit Device

Installation Instructions

Grade 1

I-ED00792

REV 3

Page 10 of 11

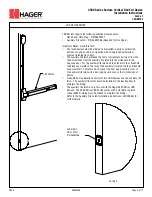

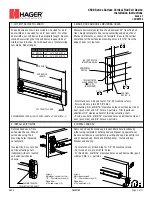

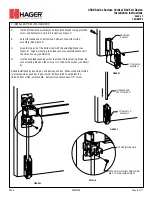

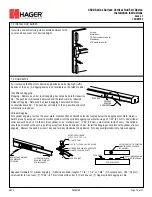

13. INSTALL ROD GUIDES

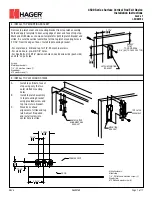

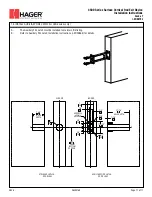

14. DOG DEVICE

Install top and bottom rod guides centered between latch

cover and head cover or at desired height.

For increasing the life of this device, dog device down during high traffic

periods of the day. (A dogging device is not available on fire rated models.)

Hex Wrench Dogging:

Dogging - Depress push bar, insert dogging hex wrench and turn clockwise

35˚. The push bar will remain depressed and the latch will stay retracted.

Release Dogging - Hold push bar, insert dogging hex wrench and turn

counterclockwise 35˚. The push bar will return to the up position and latch

will extend to lock door.

Screws:

Metal door -

10-24 machine screws (4)

Wood door -

#10 wood screws (4)

PUSH BAR

HEX WRENCH

RELEASE

DOGGING

DOGGING

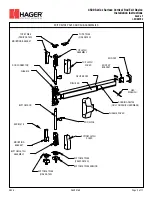

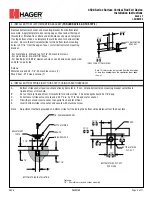

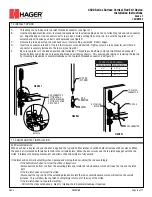

Cylinder Dogging:

For cylinder dogging, remove the cover plate. Remove the hex wrench extension located below the dogging cover plate, which is

held in place by a magnet. Install a mortise cylinder into the cylinder dogging cover plate using an 11/32” (8.7 mm) solid cylinder

collar and cash box nut. On the mortise cylinder, use a “standard cam” (.723” (18 mm), screw center to tip of cam). The cylinder

should be oriented so the cam is pointing away from the exit device push bar. Install the dogging cover plate with cylinder and test

dogging. Depress the push bar, insert key, and turn key clockwise to dog device. Turn key counterclockwise to release dogging.

SLIDE HEX WRENCH

DOGGING PLATE OUT

OF DEVICE BODY

REMOVE AND DISCARD

HEX WRENCH

EXTENSION

MORTISE CYLINDER

SIZES 1-1/8" TO 1-3/8"

WITH STD CAM

11/32" [8.7] STOCK SOLID COLLAR

CYLINDER DOGGING COVER PLATE

CYLINDER LOCKING PLATE

CASH BOX NUT

PUSH BAR

ORIENT CAM SO IT IS POINTING

AWAY FROM THE PUSH BAR

(AS SHOWN)

EXIT DEVICE BODY

SLIDE CYLINDER DOGGING

PLATE INTO DEVICE BODY

Required Hardware for cylinder dogging: (1) Mortise cylinder, lengths: 1 1/8”, 1 1/4”, or 1 3/8”, (1) Standard cam, .723” (18 mm),

screw center to tip of cam, (1) 11/32” (8.7 mm) stock solid collar, (1) Cash box nut, (1) Hager cylinder dogging kit, No.

26490169