34

Installation

3.9.4 Sensor removal

•

If not using the ORBISPHERE 32003 insertion/extraction valve (refer to

insertion/extraction valve on page 35

) you will need to shut off the sample flow and drain the

sampling circuit of liquid.

•

Remove the sensor cable connected at the sensor end.

•

Hold the sensor body in one hand to avoid rotation, and unscrew the collar with the other

hand.

•

Pull the sensor straight out of the socket or flow chamber.

•

Install sensor storage cap and sensor base (to protect the connection).

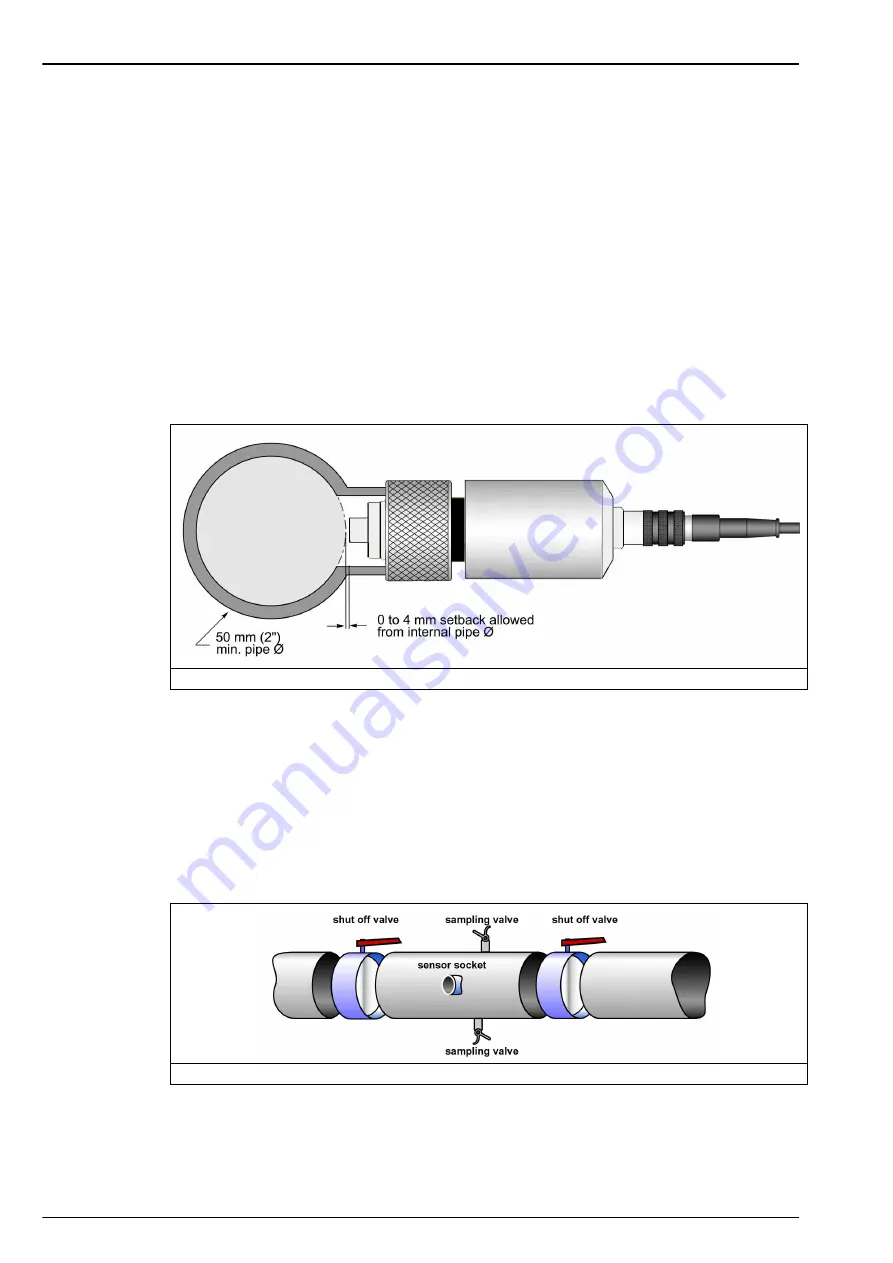

3.9.5 Weld-on stainless steel socket

The ORBISPHERE 29501 weld-on sensor socket can be used to install a sensor into a stainless

steel pipe (min.Ø 50 mm or 2”). When welding the socket to the pipe, check that setback

between the pipe’s inner diameter and the sensor tip does not exceed 4 mm (see diagram).

Note:

Be sure to remove the two O-rings from the socket before welding and leave the sensor’s stainless

steel cap screwed on during welding to prevent thread distortion.

Recommendation:

To facilitate sensor removal and installation, we suggest installing the socket in a location where

the liquid can be drained quickly and easily. By creating a one meter long piece of pipe (refer to

) with shut off valves at both ends, just a small volume of liquid needs to be drained to

enable sensor removal.

Also, a precise sensor and socket installation can be performed in the workshop, and this

assembly can be placed in the production line with minimal down time.

Figure 20 Weld-on sensor socket

Figure 21 Installation in-line

Summary of Contents for ORBISPHERE K-M1100

Page 5: ...4 Table of Contents ...

Page 19: ...18 Specifications ...

Page 39: ...38 Installation ...

Page 45: ...44 User Interface ...

Page 48: ...47 Section 6 View Menu Figure 33 View menu ...

Page 51: ...50 View Menu ...

Page 52: ...51 Section 7 Measurement Menu Figure 36 Measurement menu ...

Page 59: ...58 Measurement Menu ...

Page 65: ...64 Calibration Menu ...

Page 66: ...65 Section 9 Inputs Outputs Menu Figure 39 Inputs Outputs menu ...

Page 68: ...67 Inputs Outputs Menu 9 4 Analog outputs Figure 40 Analog outputs menu ...

Page 75: ...74 Inputs Outputs Menu ...

Page 91: ...90 Communication Menu ...

Page 94: ...93 Section 12 Products Menu Figure 43 Products menu ...

Page 97: ...96 Global Configuration Menu ...

Page 98: ...97 Section 14 Services Menu Figure 45 Services menu part 1 ...

Page 99: ...98 Services Menu Figure 46 Services menu part 2 ...

Page 107: ...106 Maintenance and Troubleshooting ...

Page 113: ...112 Accessories and Spare Parts ...