Three Piece High Pressure Ball Valves

–

H25 Valves Series

Three Piece High Pressure Ball Valves

–

H25 Valves Series

7

Standard API-6D Tag

6.3.

Insta llation in a v ibrating e nvironm ent

When installing a cryogenic valve with an actuator in a normal vibrating environment the whole

unit

MUST

be fixed with a stable fixation to a rigid area.

When installing a cryogenic valve with an actuator in an inclination angle it is

CRITICAL

to do a

stable fixation to the whole unit to a rigid area.

For a non-cryogenic valves it is recommended to do fixation in a normal vibrating environment.

When installing a valve in a

high vibrating

environment such as for an off-road application -

please contact Habonim.

6.4.

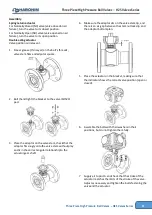

T hr e aded End Valves

6.4.1.

Valves with threaded ends should be treated as a single unit and should not be

dismantled when installing to pipeline.

6.4.2.

Before installing the valves, make sure that the threads on the mating pipe are free from

excessive grit, dirt or burrs.

6.4.3.

When tightening the valve, apply a pipe wrench or spanner to the end connector

closest to the pipe being worked, using standard piping practices.

6.4.4.

Use appropriate joining sealants material in correct quantities.

6.4.5.

If

“

back-welding

”

is required on threaded end valves, refer to the instructions for Weld

End valves or to the

“Habonim

Welding

Instructions”

bulletin.