3-11

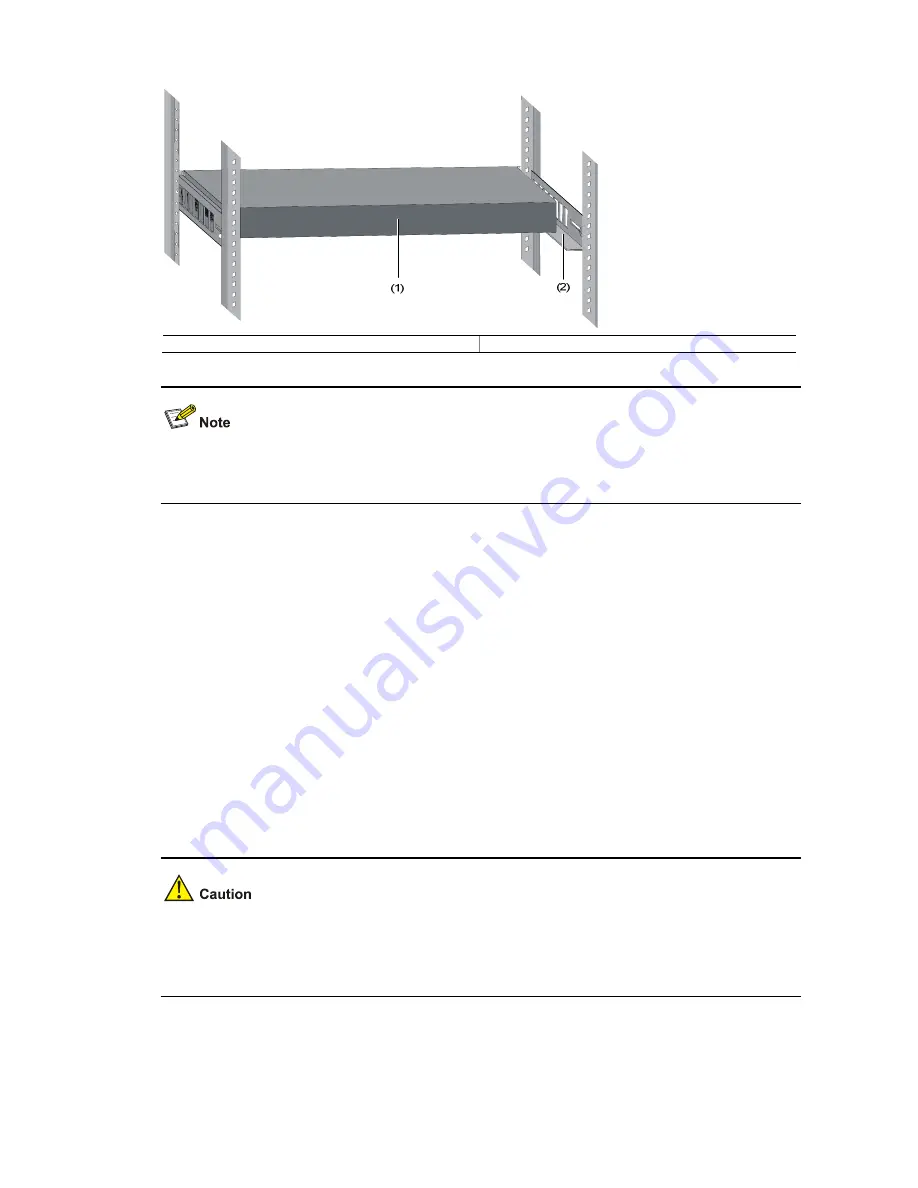

Figure 3-14

Effect diagram of front mounting bracket and guide rail installation

(1) Rear panel

(2) Guide rail

Ensure a clearance of 1U (44.45 mm, namely, 1.75 inches) between devices for the purpose of heat

dissipation.

Mounting the Switch on a Workbench

In many cases, standard 19-inch racks are not available. Therefore, switches are often placed on clean

workbenches. To place your switch on a workbench, you simply need to:

z

Make sure that the workbench is clean, flat, and sturdy.

z

Make sure that the environment is well ventilated and allows 10 cm (3.94 in.) of space around the

chassis for heat dissipation.

z

Do not place heavy objects on your switch.

z

In the case of stack application, the vertical distance between two switches must be at least 1.5 cm

(0.59 in).

Connecting the Grounding Cable

z

Correctly connecting the chassis grounding cable is crucial to the lightning protection and

electromagnetic susceptibility (EMS) of a switch.

z

The power and grounding terminals in this section are for illustration only.

The power input end of the switch is connected with a noise filter, whose central ground is directly

connected to the chassis, forming the so-called chassis ground (commonly known as PGND). This

chassis ground must be securely connected to the earth so that the faradism and leakage electricity can

be safely released to the earth, enhancing the EMS capability of the switch.