Exhaust Venting

This heater is designed to exhaust the products of combustion

(

fl

ue gases) to the outdoors using a sealed piping system.

Table 1 lists the allowable vent materials and sizing

information. Figure 16 shows the general venting layout

while Figures 17-19 show various end termination details and

clearances. Connection of the venting piping to the blower is

shown in Figures 21-25.

Correct installation of the venting system is essential to the

safe and ef

fi

cient operation of this water heater. Vent piping

must be installed in accordance with all applicable national and

provincial codes. All installations shall meet the requirements

as stated in the latest edition of the

"Natural Gas and

Propane Installation Codes" CSA-B149-1

.

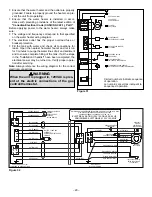

STREET ELBOW

NORMAL ELBOW

150mm

(6 in.) min.

BACK TO BACK ELBOWS

90° LONG SWEEP ELBOW

(LESS RESTRICTIVE)

90° SHORT SWEEP ELBOW

(MORE RESTRICTIVE)

PREFERRED PRACTICE

PREFERRED PRACTICES

NOT RECOMMENDED

Figure 13

Note:

The information provided in Figure 13 is intended as a

guideline for good vent installation practices only and is not

intended to restrict venting options beyond those restrictions

established by the latest edition of the

"Natural Gas and

Propane Installation Codes" CSA-B149-1

or any applicable

local and provincial codes.

High Ambient Temperature Installations

This heater requires room air to lower the

fl

ue gas temperatures

before the gases pass through the vent system. The dilution

air inlets are located on the rear of the blower assembly (see

Figures 5 & 21). As the room temperature rises, the ability

to lower the

fl

ue gases lessens so special attention to the

choice of venting material is required. Establishing the ambient

temperatures where the heater and the venting is installed is

very important, especially in regions with warmer climates or

any region that experiences hot summers. Ambient conditions

hotter than 43°C (110°F) require that the venting material be

either CPVC or polypropylene. Areas that can experience

high ambient environments include closets, alcoves, areas

under staircases, attics especially in metal roofed buildings,

areas with restricted air movement, rooms with large solar

gains, metal sheds, industrial or commercial enterprises

and venting systems exposed to direct sunlight. For high

temperature environments, obtain high limit switch upgrade

Kit # 9008306015 and use the higher rated vent piping.

Important Notes and Warnings

This heater is certified to be installed using Schedule

40 PVC or CPVC or polypropylene plastic vent material.

All jurisdictions require that this material is approved to

ULC S636. Only use approved material. All venting mate-

rial and components must be joined with the approved

primer/cleaner and solvent cement.

Do not common vent this heater with any other appli-

ance.

During operation the plastic piping will expand as it heats

up and contract as it cools down. This is normal for this

type of venting. Rigidly fastening the vent piping can

cause undue stress that may result in the cracking or

fracturing the vent piping material. A fracture of the vent-

ing pipe may pose a serious safety hazard. To prevent

stressing of the vent system, all hangers and supports

must allow the vent piping freedom to move.

Use long sweep elbows wherever possible. Closely-

coupled elbows and short radius elbows can reduce the

venting capacity.

All power vented water heaters generate a certain

amount of operational noise. In order to minimize noise

transmission to the support structure, it is recommended

to use isolation pads between the pipe hangers and the

vent pipe.

Most power vent installations develop some condensa-

tion in the vent piping. When using long runs of venting

or when the venting passes through cold or unheated

areas, considerable amounts of condensate from the flue

gases can develop. Provision must be made for the con-

densate to drain freely from the system or to be collected

in a condensate trap(s) that can be drained. Damage or

fracture of the vent piping may occur if the condensate

is allowed to collect and freeze. Pooling of condensate

can restrict airflow and can cause nuisance failures of

the system.

•

•

•

•

•

•

–

11

–