English (GB)

16

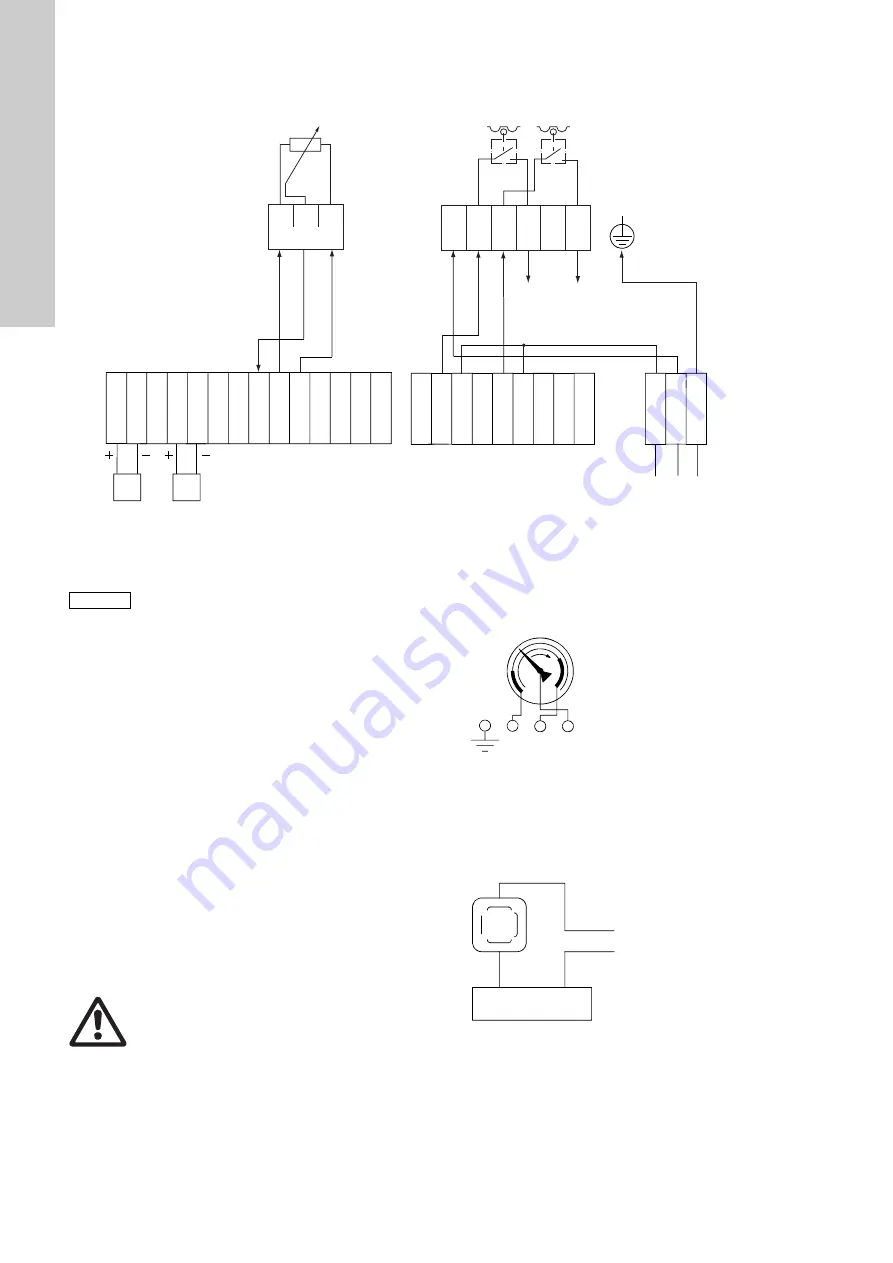

• Connect the terminals to the corresponding terminals on the external controller (Conex

®

DIS-2Q in the example) as shown in the

connection diagram.

Fig. 21

Terminal connection diagram for Conex

®

DIS-2Q on a servomotor with reversing potentiometer

Electrical connection

1. Unscrew the hood screws and remove the hood.

2. Establish the electrical connections in accordance with the

circuit diagram; see fig.

– Connect terminals 18, 19 and 20 in accordance with

requirements; voltage < 50 V.

3. Determine the direction of rotation and, if necessary, correct it.

Determining the direction of rotation

The internal wiring means that the direction of rotation (looking

through the drive towards the output shaft) and limit switches are

assigned as follows:

• If the mains voltage is present at terminal 2, the output shaft

rotates anticlockwise (in the direction "open/max.").

– This direction of rotation is restricted by the upper switch

(max.). If the switch is activated, the mains voltage is

present at terminal 4.

• If the mains voltage is present at terminal 3, the output shaft

rotates clockwise (in the direction "close/min.").

– This direction of rotation is restricted by the lower switch

(min.). If the switch is activated, the mains voltage is present

at terminal 5.

• If the drive rotates in the opposite direction to the control

commands, swap over the connections of terminals 2 and 3.

Close the hood again and tighten the hood screws.

Vacuum meter with limit contacts (option)

• Connect the terminals of the plug with the corresponding

terminals of an external evaluation device according to the

connection chart.

Fig. 22

Connection chart vacuum of meter with limit contacts

Vacuum sensors (option)

• Connect the terminals of the plug with the corresponding

terminals of an external evaluation device according to the

connection chart.

Fig. 23

Connection chartof vacuum sensor

TM

04 095

4 400

9

15 16 17 18 19 20 21 22 23

24 25 26

L1

P E

1

2

3

4

5

6

7

8

9 10 11 12 13 14

IDM

SL (max.) SR (min.)

open

min.

max.

close

N

2

3

4

5

18 19 20

< 50 V

start

slider

end

< 50 V

1

N

PE

potential-free relay outputs

Measuring amplifier

Feedback potentiometer

Note

See Section

for warnings and notes relating to

electrical connection!

Warning

The internal wiring of the drive must never be

modified.

TM

04

08

13

09

08

T

M

04

08

14

09

0

8

PE

1

2

3

1

2

3

24 V DC

+

-

4-20 mA

+

-